Panshul Technologies is an authorized SOLIDWORKS Reseller in Mumbai, Navi Mumbai, Thane, Nashik | Certified Platinum Level Support partner of DASSAULT Systemes

Our Customer's

At Panshul Technologies LLP, we collaborate with leading industry partners to deliver the most advanced CAD and engineering solutions. As an Authorized SOLIDWORKS Reseller, we work in close partnership with Dassault Systems.

About Panshul Technologies LLP

9+ Years of Delivering SOLIDWORKS Excellence

Panshul Technologies LLP is a certified Authorized SOLIDWORKS Reseller based in Mumbai, Maharashtra, actively serving businesses in Mumbai, Navi Mumbai, Thane, and Nashik. Founded in 2016, we have built a reputation for delivering value-added CAD solutions with ELITE Support to our customers.

With over 9 years of experience, our mission is to encourage businesses with innovative design tools like 3D CAD Modelling, Simulation, Product Visualisation, product data management & more. Our expertise spans industries and project sizes, and our goal is always the same: helping you achieve design excellence.

Why Choose Panshul Technologies?

Value-Added Services

We understand that every organization has unique needs. That’s why we tailor our 3D CAD Solutions offerings to meet specific design and engineering challenges.

Value-Added ServicesCustomized Solutions

We analyse your workflows and deliver optimized solutions to you as per your product needs. Panshul Technologies’ Support team is always here to give you support.

Customer-Centric Approach

At Panshul, we prioritize your success. As a dedicated Reseller of One of the best CAD software, we stay committed to your long-term satisfaction with proactive support and solution upgrades.

Quick Query Resolution

With a record of over 8,000 support calls resolved, our 24-hour support model ensures minimal downtime for your business.

Comprehensive Training & Support

Whether you're a new user or aiming for to be a Professional SOLIDWORKS user, our expert-led training will help you to master the software quickly and effectively.

Industry Expertise

We’ve served companies in Automotive, Aerospace, Oil & gas, Electronics, and more—delivering Simulation and Modelling tools that solve real-world problems.

At Panshul Technologies, your success is our priority. As your trusted engineering solutions partner, we are committed to empowering your business with the best CAD solutions, ensuring innovation and growth.

What we do

Our Expertise

Software Licensing

As a SOLIDWORKS reseller, we provide flexible purchasing plans including Perpetual Licensing, Subscription-based Access, and 3DEXPERIENCE SOLIDWORKS.

Training & Enablement

We will provide training to to your employees & solve their queries. This training will be done using curriculum provided by the SOLIDWORKS as per global standards.

Professional Services

From CAD implementation to PDM configuration, our team will offer all the solution and services that solve your design and collaboration challenges.

Technical Support

At Panshul Technologies, we are always here to assist you regarding SOLIDWORKS Products Portfolio. From Installation to migration, changing subscription plan.etc.

Products And Solutions

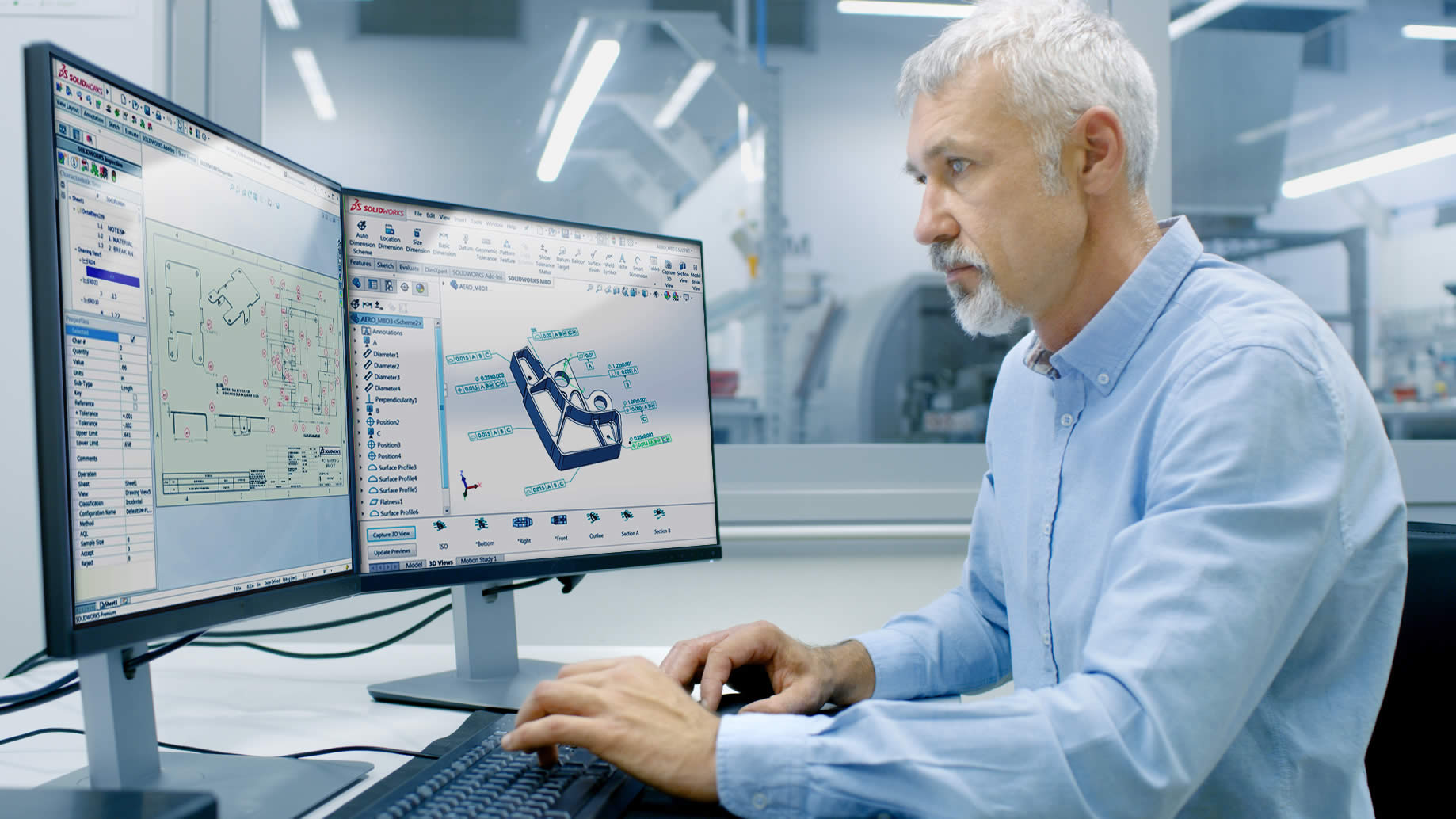

SOLIDWORKS 3D CAD

Reduce product development time and improve accuracy with intuitive 3D Modelling tools. The latest updates in SOLIDWORKS software enhance speed and allow cloud access for real-time collaboration.

3DEXPERIENCE Works

For companies looking to scale, we offer support for cloud-based platforms that unite your organization—from engineering to sales—all connected to you with one ecosystem.

SOLIDWORKS Visualize

SOLIDWORKS Visualize is a tool that turns 3D CAD models into high-quality, photorealistic images and animations. It helps you showcase your designs for presentations, marketing.etc

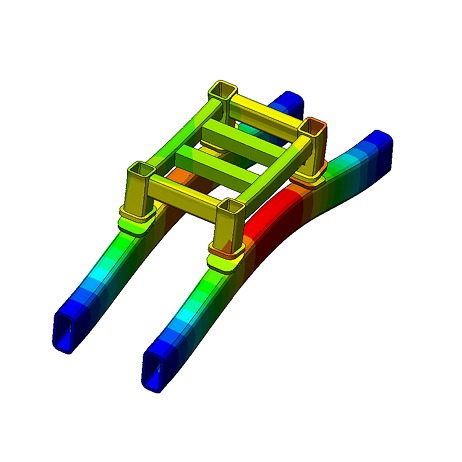

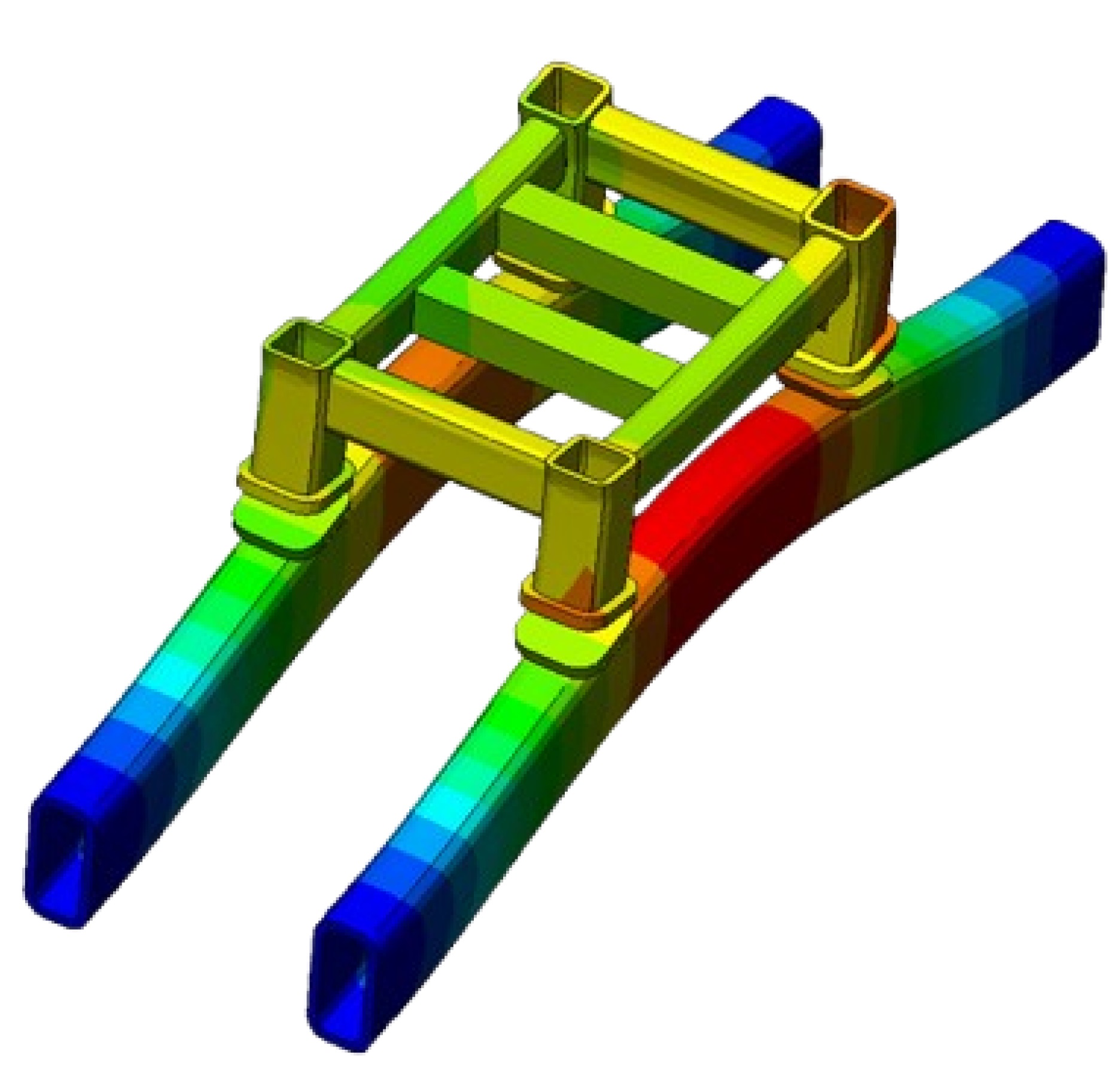

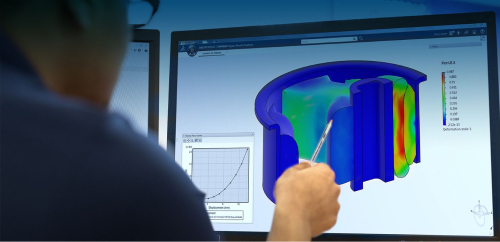

SOLIDWORKS Simulation

Before building physical prototypes, test your ideas with Simulation Tools. It helps you evaluate stress, load, and durability—saving both time and manufacturing costs.

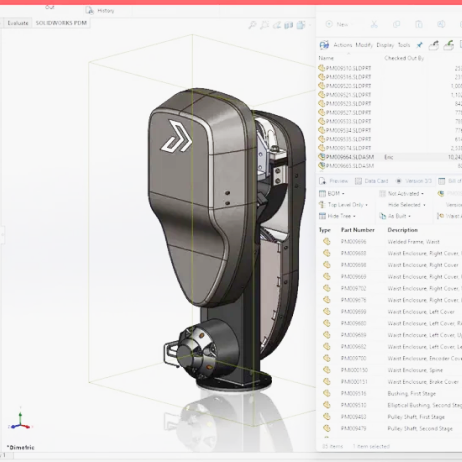

SOLIDWORKS PDM

Secure your design data and control access across teams with SOLIDWORKS PDM, fully integrated into your workflow for better collaboration and compliance.

What our customer say's

2. Very fast reply when required

3. Any Type of Query regarding Engineering drawing & softwares will be solved.

4. Demo of any product related to engineering drawing or solution can be arranged

Rating from our long term business relationship with Shah Group viz. Piano Presitel, Windston Springs PVT LTD & Aquel with Panshul Technologies LLP.

Our Milestones

In our journey as a trusted CAD Solution provider, we have accomplished the following:

Explore our recent webinar : SOLIDWORKS Simulation

In this webinar we have discussed the following points related to SOLIDWORKS Simulation:

- Advance tools in SOLIDWORKS Simulation

- What’s new in SOLIDWORKS 2025

- How you can reduce your cost of production

- Simulation Tips & Tricks

BUYING PLANS FOR SOLIDWORKS

Perpetual License

Own your SOLIDWORKS software license with life time access. Ideal for organizations with long-term, stable usage needs.

- One-time purchase, lifetime ownership

- Optional Subscription Plans

- Access to all professional tools

- Technical Support

Subscription-Based License

A flexible plan for dynamic teams. Pay annually and enjoy full access, updates, and support.

- Lower upfront cost, yearly renewal

- Free Upgrade to newer Versions of SOLIDWORKS

- Bundled Packages as per your needs

- Ideal for scaling and short-term projects

3DEXPERIENCE SOLIDWORKS

Cloud-connected SOLIDWORKS software for real-time collaboration and scalability across departments.

- Access your design from anywhere

- Design products from any device

- Team Collaborative & project Management Tools

- No Hardware Requirement

3D DESIGN & DRAFTING

We have guided many companies to bring their historic 2D drawing library up-to-date. We can help you in transforming from 2D to 3D using SOLIDWORKS.

VISUALIZATION & ANIMATION

We have guided many companies to bring their historic 2D drawing library up-to-date. We can help you in transforming from 2D to 3D using SOLIDWORKS.

FEA SIMULATION

To stay competitive in today’s market your products need to last longer than the competition, be cheaper to manufacture, and deliver a more compelling customer experience.

ABOUT 3D EXPERIENCE

3DEXPERIENCE SOLIDWORKS integrates SOLIDWORKS with a cloud-based platform, enabling real-time collaboration, secure data management, and seamless workflows. It boosts productivity, reduces IT costs

Our Recent Blogs

Upcoming Webinars

Make Product Development Easier & Cost-Effective With SOLIDWORKS Simualtion

- List Item #1

- List Item #2

- List Item #3

Let’s Build the Future Together

At Panshul Technologies, your innovation is our mission. Whether you're upgrading from 2D drafting or integrating real-time Simulations, we’ll help you to navigate every step of your product development journey. Contact us today to learn how our 9+ years of CAD excellence and a partnership with DASSAULT SYSTMES can transform your Product Development Journey.

FAQs

Why should I buy SOLIDWORKS from Panshul Technologies?

As an Authorized SOLIDWORKS Reseller in Mumbai, Navi Mumbai, Thane, and Nashik, Panshul Technologies offers localized support, expert training, and genuine software licenses—all under one roof. Our team ensures smooth onboarding, timely upgrades, and personalized assistance, helping you get the most from your SOLIDWORKS investment.

Can I try SOLIDWORKS before purchasing?

Yes, a free demo of SOLIDWORKS is available! Whether you’re an engineer, manufacturer, or product designer, we’ll walk you through real-world applications to help you evaluate the right tools for your specific needs.

How difficult is it to learn the different SOLIDWORKS tools?

SOLIDWORKS solutions have been designed to be highly intuitive and easy to learn and while they feature powerful tools, most users pick up the software quickly. With multiple modes of training for every learning style available from Hawk Ridge Systems, new user ramp-up time can be shortened even further.

Does SOLIDWORKS work on the cloud?

Yes! 3DEXPERIENCE SOLIDWORKS offers a cloud-based environment, letting you access your design files, manage revisions, and collaborate with team members—all without needing powerful local hardware.

What are the different ways to buy SOLIDWORKS?

SOLIDWORKS offers three flexible purchase options to suit different business needs—

- Perpetual License – Own SOLIDWORKS permanently with a lifetime access for the software.

- Subscription License- Get full access with monthly or yearly payments, including updates and support.

- 3DEXPERIENCE SOLIDWORKS- Collaborate, manage data, and design in real time through a secure, cloud-connected platform with automatic updates.