SOLIDWORKS for Aerospace

- Home

- Aerospace

The aerospace sector is one of the most demanding industries, covering everything from aircraft and spacecraft to satellites and defence systems. With a strong focus on lightweight materials, safety, and efficiency, aerospace manufacturing relies on highly precise engineering and smart design practices. We offer customized solutions for aerospace companies, helping them meet strict regulations, enhance performance, and innovate confidently

Panshul Technologies is an authorized SOLIDWORKS Reseller for Aerospace Design in Mumbai, Navi Mumbai, Thane, Nashik | Book a Free Demo & Get the Best Price on SOLIDWORKS CAD

Aerospace engineering

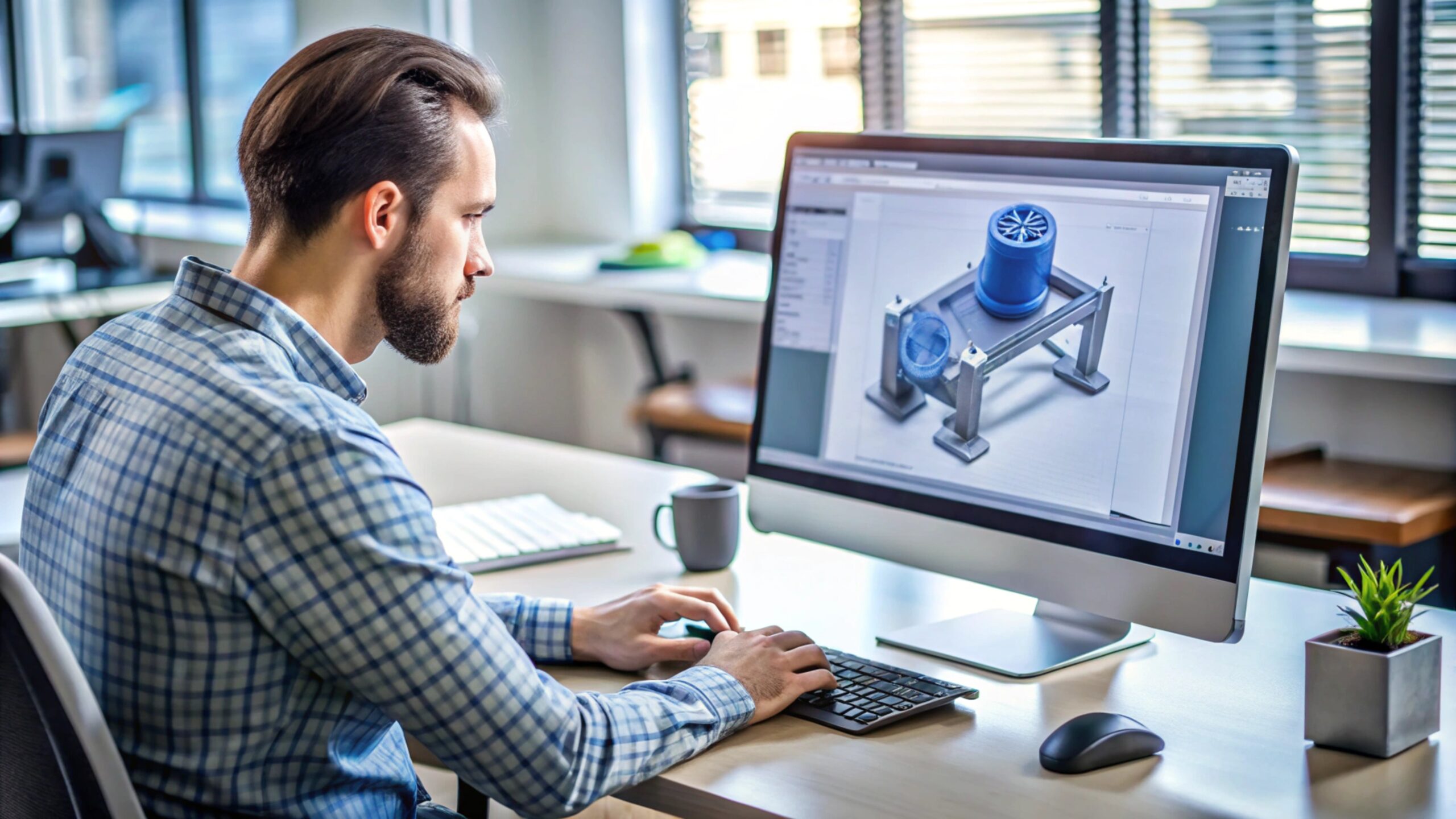

Precision is the backbone of the aerospace industry—and SOLIDWORKS brings that precision to life. Engineers use this robust design platform to model and refine complex aerospace components, reducing manual errors and improving build quality. With built-in simulations, teams can test stress, heat, and vibration behaviour before the first prototype is even built. From initial concepts to final assemblies, SOLIDWORKS helps aerospace manufacturing teams stay agile, cost-effective, and compliant with industry standards.

To know more

Looking for SOLIDWORKS in Aerospace

How SOLIDWORKS Helps the Aerospace Industry

Accelerated Product Development Cycles

SOLIDWORKS helped aerospace companies dramatically reduced time-to-market with tools for rapid prototyping, simulation, and design validation.

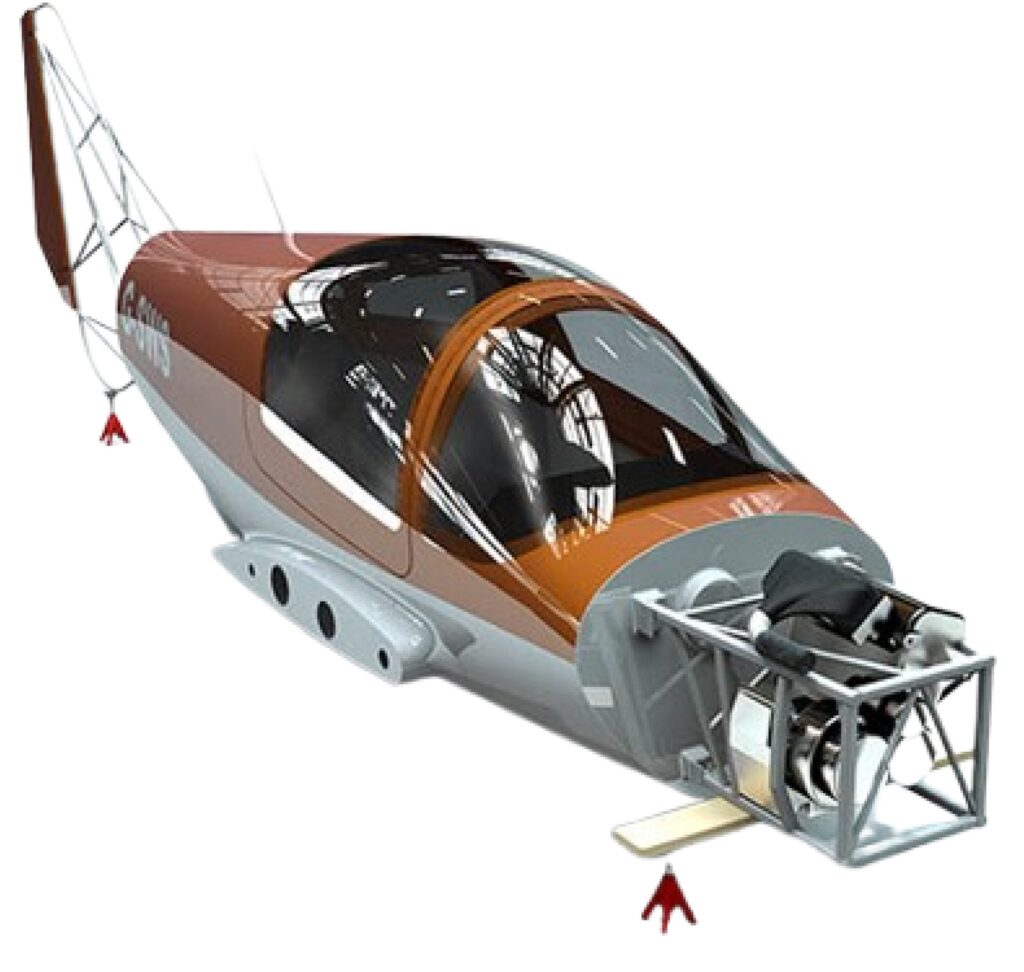

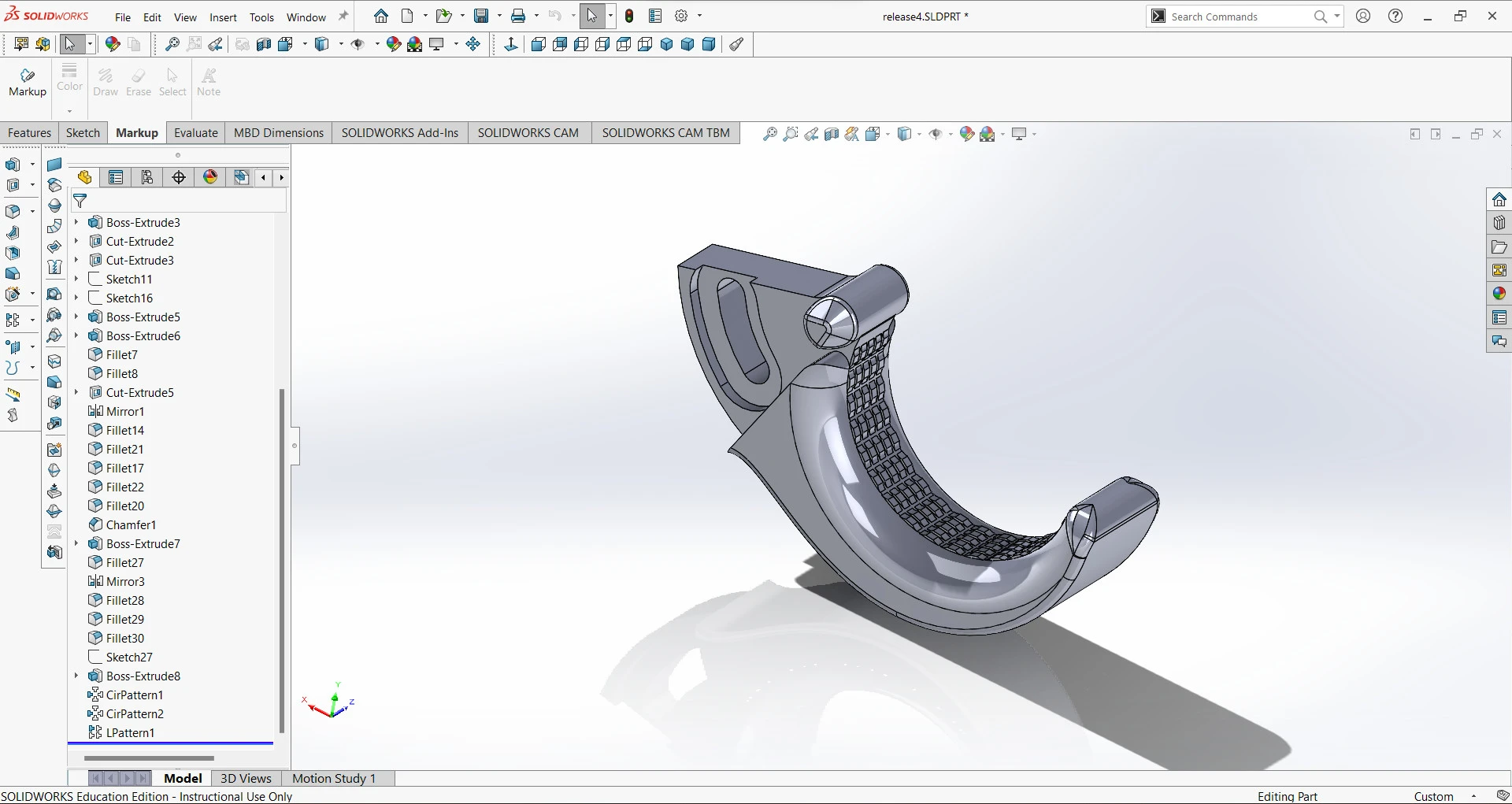

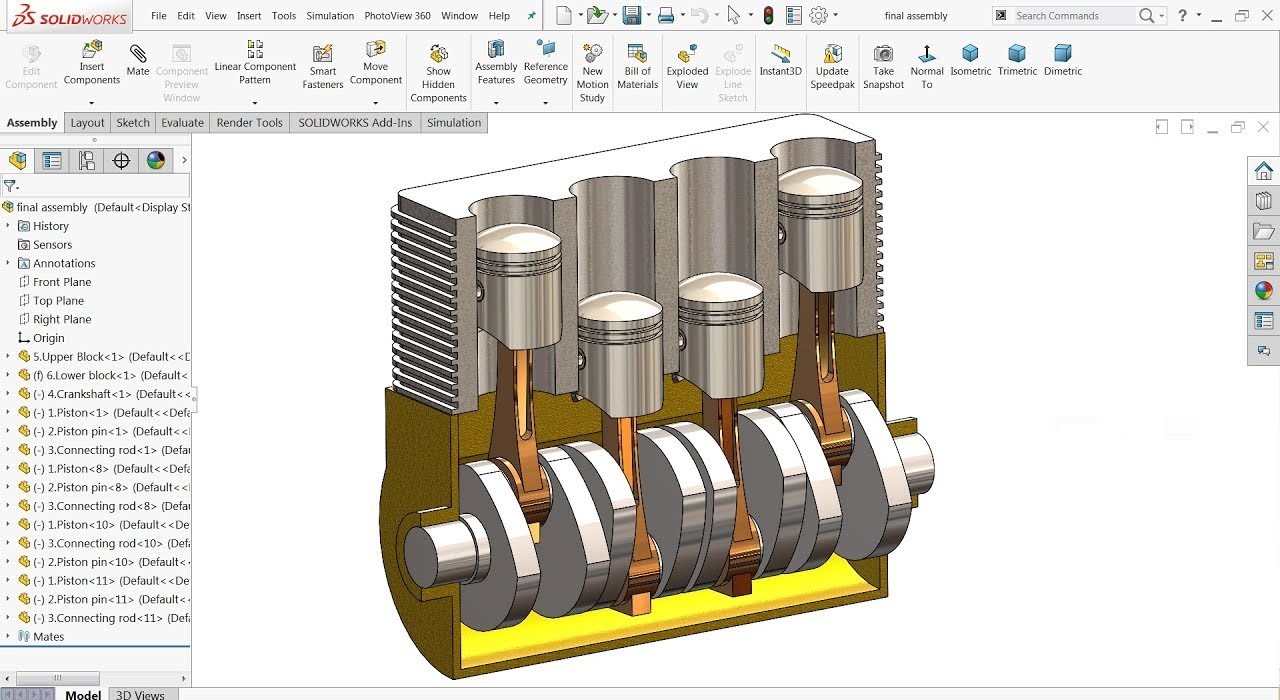

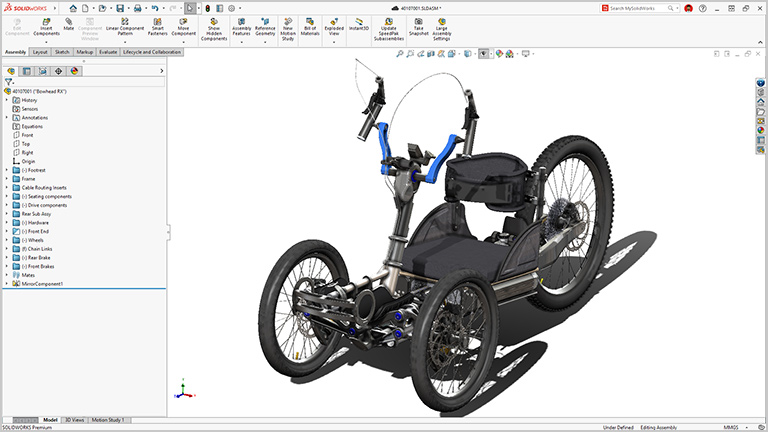

Advanced 3D Modeling for Complex Geometry

Engineers created intricate designs—like fuselages, turbine blades, and wing structures—with high precision using SOLIDWORKS’ advanced 3D modeling tools.

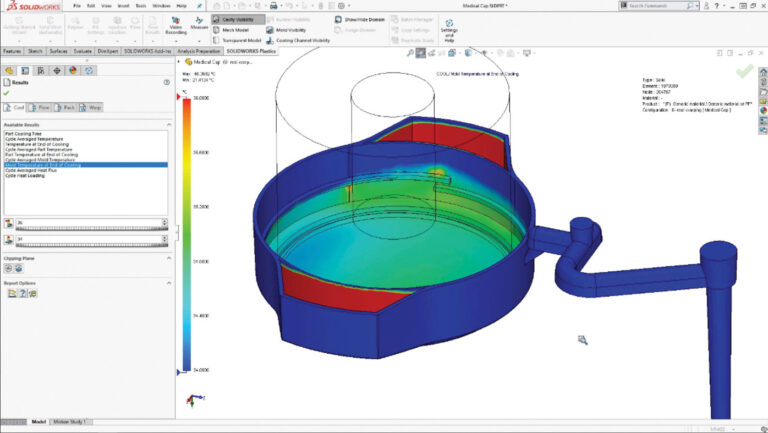

Integrated Simulation for Structural & Thermal Analysis

Simulation allowed engineers to assess structural integrity through thermal and fatigue analysis—eliminating the need for early physical tests.

Seamless Collaboration Across Engineering Teams

With SOLIDWORKS PDM, design data was easily managed and shared, version-control issues in large aerospace projects.

Compliance with Industry Standards

Aerospace companies met regulatory requirements (AS9100, FAA) faster using SOLIDWORKS’ traceability features and documentation tools.

Weight Optimization and Material Usage Efficiency

SOLIDWORKS helped engineers to optimize material usage with topology analysis- crucial for weight reduction and fuel efficiency.

Related Products

SOLIDWORKS Premium

Benefits:

• Ideal for complex aerospace parts and assemblies

• Precise 3D modeling for lighter, more aerodynamic designs

• Includes piping and tubing routing tools for aircraft systems

SOLIDWORKS Simulation

Benefits:

• Test strength, durability, and safety under simulated conditions

• Analyse vibration and heat—critical in aerospace operations

• Reduce physical prototyping costs significantly

SOLIDWORKS Flow Simulation

Benefits:

• Run CFD analysis on aircraft parts

• Improve cooling systems for avionics

• Predict performance in harsh thermal conditions

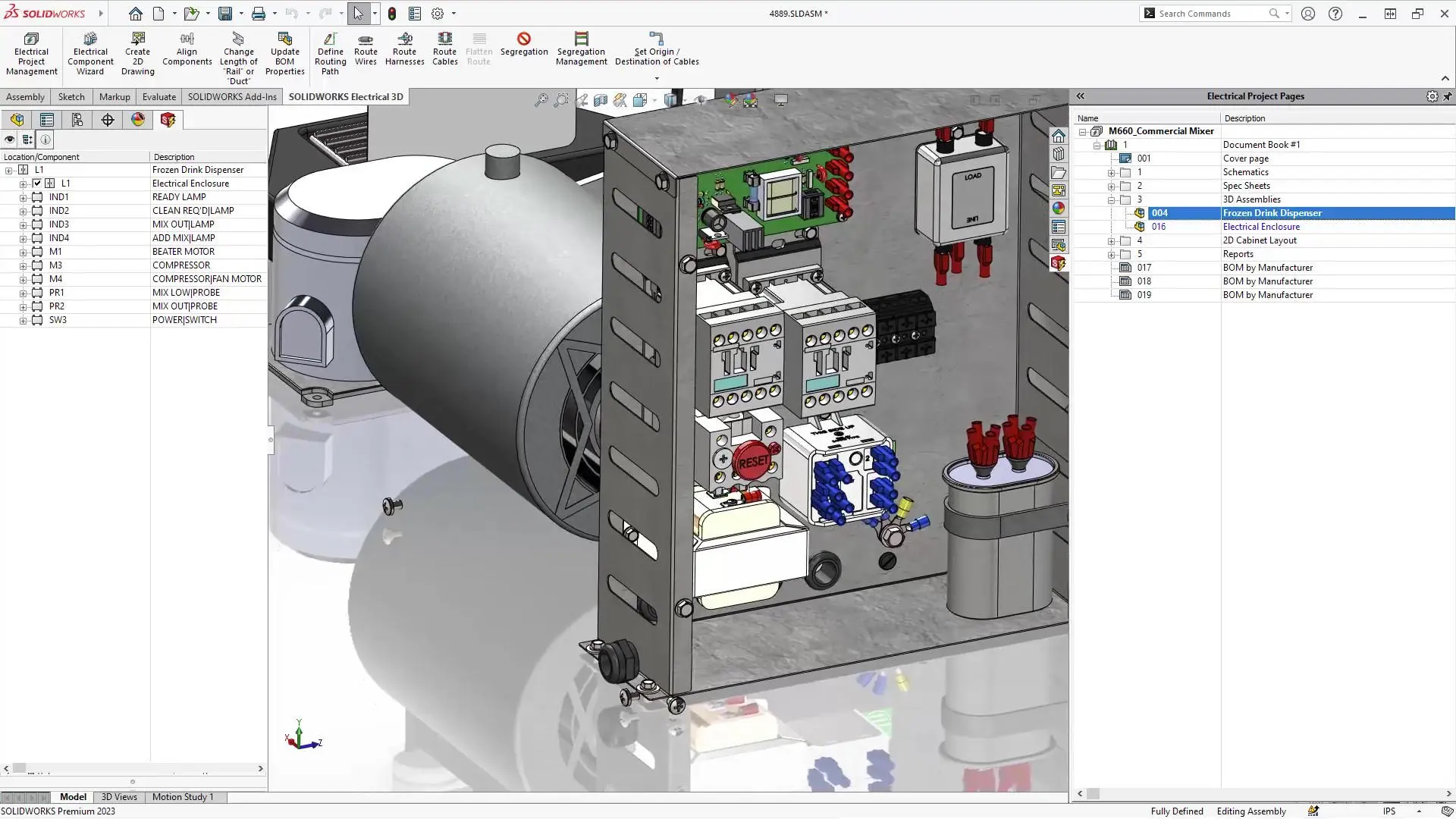

SOLIDWORKS Electrical

Benefits:

• Design complete aircraft wiring systems

• Ensures integration between electrical and mechanical design

• Automate harness layouts and minimize wiring errors

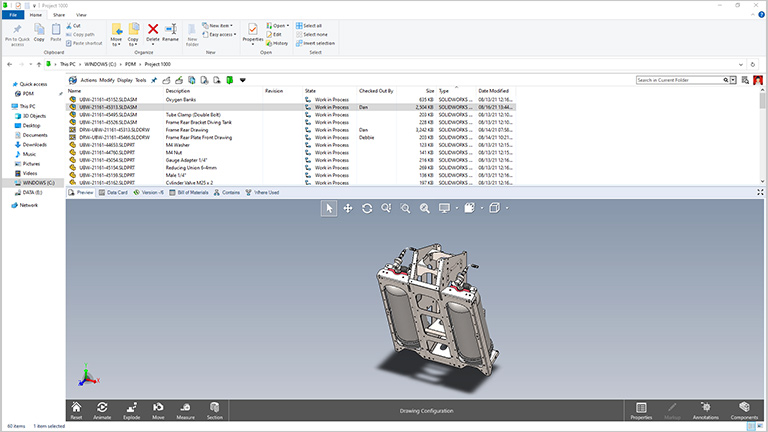

SOLIDWORKS PDM (Product Data Management)

Benefits:

• Centralize and protect design data

• Maintain traceability for certification readiness

• Improve team collaboration and data sharing

3DEXPERIENCE Works

Benefits:

• Cloud-based collaboration for dispersed teams

• Manage tasks, feedback, and part lifecycles in one place

• Ideal for suppliers and partners across locations

Related Articles

FAQs

Why should I buy SOLIDWORKS from Panshul Technologies?

As an Authorized SOLIDWORKS Reseller in Mumbai, Navi Mumbai, Thane, and Nashik, Panshul Technologies offers localized support, expert training, and genuine software licenses—all under one roof. Our team ensures smooth onboarding, timely upgrades, and personalized assistance, helping you get the most from your SOLIDWORKS investment.

Can I try SOLIDWORKS before purchasing?

Yes, a free demo of SOLIDWORKS is available! Whether you’re an engineer, manufacturer, or product designer, we’ll walk you through real-world applications to help you evaluate the right tools for your specific needs.

How difficult is it to learn the different SOLIDWORKS tools?

SOLIDWORKS solutions have been designed to be highly intuitive and easy to learn and while they feature powerful tools, most users pick up the software quickly. With multiple modes of training for every learning style available from Hawk Ridge Systems, new user ramp-up time can be shortened even further.

Does SOLIDWORKS work on the cloud?

Yes! 3DEXPERIENCE SOLIDWORKS offers a cloud-based environment, letting you access your design files, manage revisions, and collaborate with team members—all without needing powerful local hardware.

What are the different ways to buy SOLIDWORKS?

SOLIDWORKS offers three flexible purchase options to suit different business needs—

- Perpetual License – Own SOLIDWORKS permanently with a lifetime access for the software.

- Subscription License- Get full access with monthly or yearly payments, including updates and support.

- 3DEXPERIENCE SOLIDWORKS- Collaborate, manage data, and design in real time through a secure, cloud-connected platform with automatic updates.