Achieving consistent product quality is not just about inspecting at the end—it’s about building quality into every stage of the design and manufacturing process. By combining SOLIDWORKS Inspection, MBD, and Simulation, manufacturers can establish a tightly integrated feedback loop that closes the gap between design intent, production, and performance validation.

It all begins with SOLIDWORKS MBD, where design teams embed Product Manufacturing Information (PMI) directly into 3D models. These models—with dimensions, tolerances, and material specifications—become the single source of truth. SOLIDWORKS Inspection can then pull this data to generate ballooned inspection reports, ensuring every measured feature ties directly to the model’s design intent.

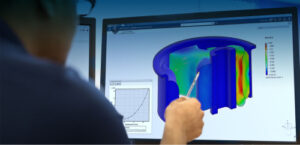

Add in SOLIDWORKS Simulation, and that same model can be tested for mechanical performance, thermal loads, and stress behavior. The results highlight critical features that require closer inspection or tighter tolerances. These insights can be looped back into the inspection process, creating an adaptive and proactive quality control system.

This integration reduces redundant data entry, minimizes human error, and improves cross-functional collaboration. Design changes flow downstream instantly, while quality teams receive real-time updates to inspection plans. The result? Reduced quality escapes, faster time to market, and better alignment across departments.

Furthermore, digital traceability across design, simulation, and inspection strengthens compliance efforts. Whether for internal audits or regulatory certification, this closed-loop approach provides complete visibility and a robust digital paper trail. Companies aiming for ISO 9001, AS9100, or FDA standards benefit from this unified framework.

By using all three tools in concert, organizations can achieve quality by design—where validation and verification are built into the product lifecycle from start to finish. This not only ensures better products but creates a culture of continuous improvement driven by data and digital innovation.