In the modern consumer market, customization is becoming a key factor in attracting and retaining customers. Consumers are no longer satisfied with generic products; they want items that cater to their specific needs and preferences. The ability to offer customization at scale presents significant challenges for manufacturers in terms of design complexity, production efficiency, and cost control. SOLIDWORKS provides the ideal platform for designing customized consumer products that meet these market demands while maintaining efficiency in production.

One of the core strengths of SOLIDWORKS is its ability to work with parametric design, which allows manufacturers to create flexible product models that can be easily adjusted to accommodate different customer specifications. For example, in the fashion industry, manufacturers can use SOLIDWORKS to design customized apparel or accessories by adjusting dimensions, colors, and textures based on customer preferences. This capability enables manufacturers to offer a high degree of personalization without the need for completely new designs for every individual customer.

SOLIDWORKS also supports product configurators, which are interactive tools that allow customers to select and customize various product options. For instance, a customer could configure a pair of shoes by selecting different styles, materials, and sizes through a virtual configurator, and SOLIDWORKS would generate a customized product design in real-time. This automation eliminates errors that could arise from manual customization, allowing businesses to efficiently manage a wide variety of options while providing a personalized experience to customers.

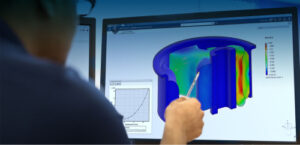

Additionally, SOLIDWORKS’ powerful simulation tools help ensure that customized products will meet the same high-quality standards as mass-produced items. Even with a high degree of customization, engineers can use SOLIDWORKS Simulation to test the structural integrity, functionality, and ergonomics of the product, ensuring that it performs well and is safe to use. For example, in designing a customized ergonomic chair, SOLIDWORKS can simulate how different body types and sitting postures would affect the chair’s performance and comfort, allowing the manufacturer to create the optimal design for every customer.

In the consumer electronics sector, the ability to customize is also becoming increasingly important. SOLIDWORKS helps companies design products such as headphones, wearable devices, or personal gadgets that can be tailored to individual preferences. Whether it’s through customizable features or personalized aesthetics, SOLIDWORKS makes it possible to create designs that offer a truly unique user experience.

In conclusion, SOLIDWORKS is a powerful tool for enabling customization in the consumer products industry. By using parametric design, product configurators, and advanced simulation tools, manufacturers can create customized products efficiently while ensuring high standards of quality. As consumer expectations continue to evolve, SOLIDWORKS provides manufacturers with the flexibility and capabilities needed to meet the demand for personalized products.