Energy plant process

- Home

- Energy plant process

The energy plant process industry is at the heart of global infrastructure, covering everything from traditional power plants to renewable energy facilities and industrial utility systems. With increasing demand for safety, compliance, and operational efficiency, this industry relies on smart engineering and innovative design. Whether you’re working with turbines, boilers, or piping networks, precision layout, fluid dynamics, and structural integrity are critical. SOLIDWORKS provides the powerful design solutions required to meet the evolving needs of energy plant and process systems

Panshul Technologies is an authorized SOLIDWORKS Reseller for Energy & Plant Process Design in Mumbai, Navi Mumbai, Thane, Nashik | Book a Free SOLIDWORKS Demo & Get Best Pricing

Energy Plant & Process

SOLIDWORKS empowers engineers in the energy plant and process sector with advanced 3D CAD tools that bring complex designs to life. From piping systems to mechanical components, SOLIDWORKS ensures accurate modeling and layout of critical infrastructure. Integrated simulations allow you to analyse how systems behave under real-world pressure, heat, and load conditions—minimizing risk and reducing physical prototyping. Whether you're designing a renewable plant or optimizing a thermal system, SOLIDWORKS improves design accuracy, speed, and compliance across every project phase.

To know more

ABOUT THE PRODUCT book a free demo

How SOLIDWORKS helped these industries

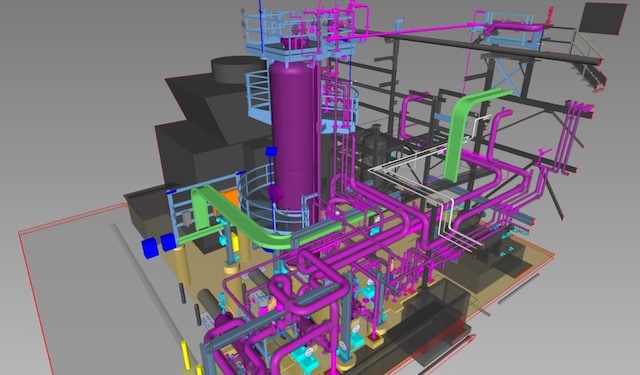

Efficient Design of Piping and Process Systems

SOLIDWORKS Routing tools enabled accurate P&ID drawings and piping layouts, helping engineers minimize manual errors

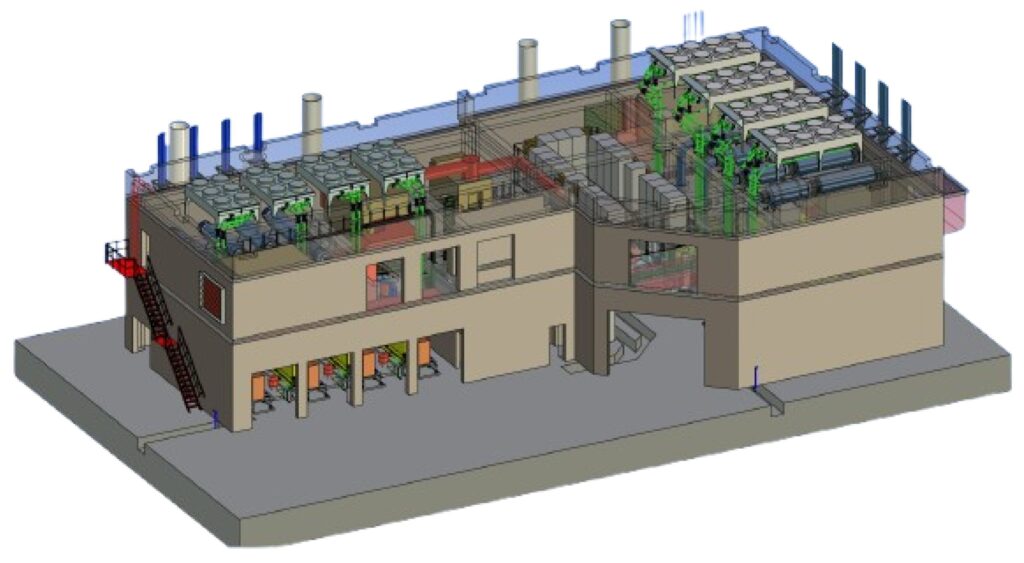

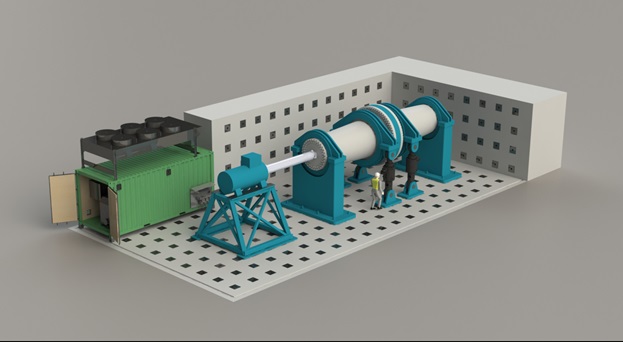

Equipment Layout and Space Management

Engineers used SOLIDWORKS for smart 3D plant layouts, ensuring efficient space use for equipment, HVAC units, and maintenance zones in energy facilities.

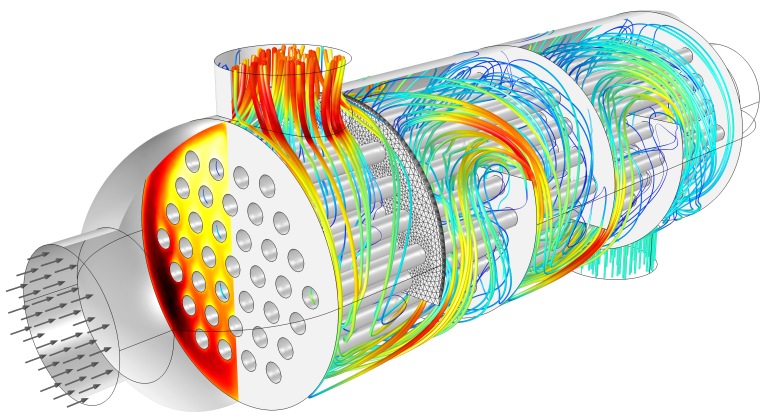

Simulation for Heat Transfer and Fluid Flow

With SOLIDWORKS Flow Simulation, teams ran thermal and CFD analysis to optimize energy system efficiency.

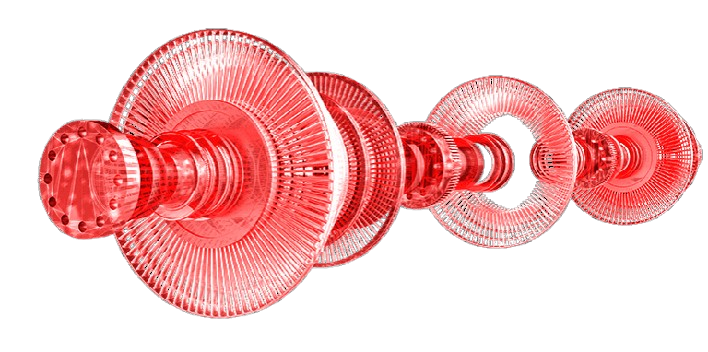

Robust Structural Design and Load Testing

SOLIDWORKS Simulation allowed engineers to validate the strength of turbine housings, boiler frames, and support systems under operational stress and vibration.

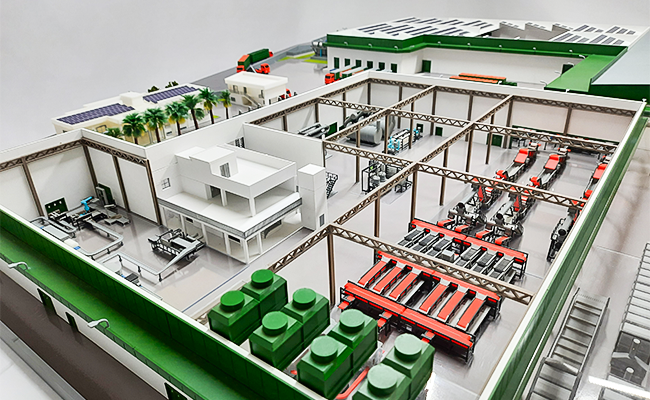

Faster Project Execution with Modular Design

Engineers leveraged SOLIDWORKS to create modular sections of power plants, speeding up on-site assembly and reducing construction lead times.

Streamlined Documentation for Regulatory Compliance

Automatic generation of BOMs, drawings, and change histories ensured adherence to global standards like ASME and IEC, critical for energy plant approvals

Related Products

SOLIDWORKS Premium

Benefits:

• Design complex piping layouts and structural systems

• Includes piping and tubing routing tools for efficient plant design

• Handles large assemblies for full plant modeling or subsystem layouts

SOLIDWORKS Simulation

Benefits:

• Analyse strength and stress of energy equipment and structures

• Simulate extreme pressure and temperature conditions with accuracy

• Optimize materials while maintaining safety and compliance

SOLIDWORKS Flow Simulation

Benefits:

• Run CFD analysis on fluid systems to improve plant efficiency

• Analyse heat transfer, pressure drops, and cooling systems

• Predict performance under various operating conditions

SOLIDWORKS Electrical

Benefits:

• Create detailed control systems and power distribution layouts

• Ensure mechanical-electrical integration within plant setups

• Save time with automated wire numbering and panel layout tools

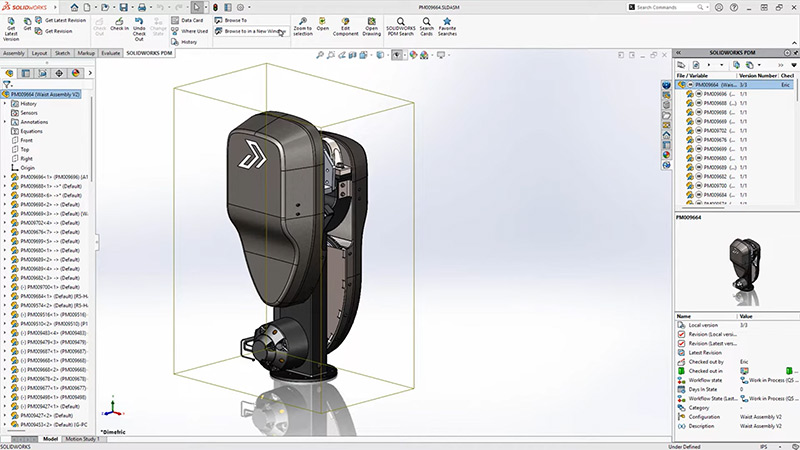

SOLIDWORKS PDM (Product Data Management)

Benefits:

• Centralize design data and revision history for energy projects

• Collaborate across disciplines—mechanical, electrical, civil

• Maintain full traceability and documentation for regulatory audits

3DEXPERIENCE Works

Benefits:

• Collaborate in real time across engineering and contractor teams

• Track project status, tasks, and design iterations from anywhere

• Streamline issue resolution and reduce downtime through cloud access