Automotive safety is a critical concern for manufacturers, governments, and consumers alike. With stricter safety regulations, evolving standards, and growing demand for reliable, crash-resistant vehicles, automakers must go beyond traditional testing methods to ensure that their designs meet global safety requirements. SOLIDWORKS, with its advanced simulation and virtual testing capabilities, offers automotive engineers a comprehensive platform for assessing vehicle safety before physical testing begins. By simulating real-world conditions virtually, manufacturers can enhance the safety, performance, and compliance of their vehicles, while reducing costs and time-to-market.

The traditional approach to automotive safety testing often involves creating prototypes and subjecting them to real-world crash tests, structural assessments, and environmental challenges. While physical tests are still necessary, they are time-consuming, expensive, and resource-intensive. In contrast, virtual testing using SOLIDWORKS allows engineers to simulate various crash scenarios, structural failures, and external forces on vehicles in a digital environment. This not only accelerates the design process but also helps identify potential issues earlier in development, leading to safer, more reliable vehicles.

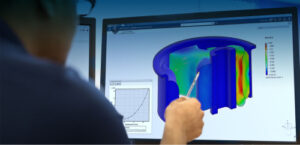

One of the key advantages of SOLIDWORKS in automotive safety testing is its ability to conduct crash simulations. Using SOLIDWORKS Simulation, engineers can create highly accurate finite element models (FEMs) of a vehicle’s body, chassis, and key components, enabling them to predict how the vehicle will respond to various impact forces. Whether testing frontal, side, or rear-end collisions, SOLIDWORKS can simulate the deformation of the vehicle’s structure and assess the behavior of safety features such as airbags, seatbelts, and crumple zones. By running these simulations virtually, engineers can optimize the design of safety systems, ensuring that they meet stringent safety standards without the need for numerous physical prototypes.

SOLIDWORKS also provides advanced tools for analyzing the strength and durability of individual components. For instance, engineers can use SOLIDWORKS to simulate the stress and strain that vehicle parts such as the frame, suspension, and door panels will experience during a collision. By understanding how components behave under various conditions, automotive designers can improve their structural integrity and minimize the risk of failure in real-world crashes. Additionally, SOLIDWORKS’ ability to run multiple simulation scenarios allows engineers to test different materials, geometries, and safety features to determine the most effective solutions for enhancing vehicle safety.

Beyond crash simulations, SOLIDWORKS’ virtual testing capabilities extend to other critical aspects of vehicle safety, including thermal performance, visibility, and driver assistance systems. For example, engineers can simulate the effects of extreme temperatures on the vehicle’s interior and electronics, ensuring that components such as batteries, wiring, and cooling systems perform optimally under harsh conditions. In the case of electric vehicles (EVs), this is particularly important to prevent overheating and ensure battery safety. By identifying potential overheating issues through virtual thermal simulations, engineers can design more robust thermal management systems, improving the overall safety and efficiency of the vehicle.

Visibility is another crucial aspect of automotive safety, and SOLIDWORKS provides tools for simulating the driver’s line of sight and visibility in various driving conditions. Engineers can model and analyze the vehicle’s windows, mirrors, and lighting systems to ensure that drivers have optimal visibility in different environments, from urban roads to rural highways. This helps ensure compliance with safety regulations related to driver visibility and accident prevention.

Moreover, with the growing trend of advanced driver-assistance systems (ADAS), SOLIDWORKS allows automotive engineers to simulate and evaluate the performance of these systems, which include features like automatic emergency braking, lane-keeping assistance, and adaptive cruise control. By virtually testing how these systems respond to real-time traffic scenarios and potential hazards, engineers can refine their algorithms and ensure that the safety systems operate effectively under various conditions.

In conclusion, the automotive industry’s focus on safety and compliance is more critical than ever, and virtual testing with SOLIDWORKS provides an efficient and effective solution to these challenges. By leveraging advanced simulation tools, automakers can identify and address safety issues early in the design process, reducing the need for costly physical prototypes and speeding up time-to-market. Whether conducting crash simulations, evaluating structural durability, testing safety features, or ensuring compliance with regulatory standards, SOLIDWORKS enables engineers to design safer, more reliable vehicles that meet the demands of modern consumers and regulatory authorities. Through virtual testing, the industry is making significant strides toward improving automotive safety, ultimately leading to fewer accidents, better protection for drivers and passengers, and a safer driving experience overall.