The medical equipment industry is heavily regulated, and manufacturers must ensure that their devices meet strict quality standards and regulatory requirements before they can be brought to market. Compliance with standards such as ISO 13485 and FDA regulations is crucial to the success of any medical device. SOLIDWORKS provides manufacturers with the tools they need to streamline the compliance process by enabling traceability, design validation, and documentation management.

SOLIDWORKS allows manufacturers to document every step of the design process, from initial concept to final prototype. This is vital for demonstrating compliance with industry standards and regulatory requirements. The software provides features like version control, design history tracking, and detailed documentation of design changes, ensuring that all modifications to the device are thoroughly recorded. This documentation is critical for satisfying regulatory bodies during audits and approval processes.

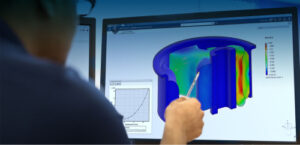

Furthermore, SOLIDWORKS integrates seamlessly with simulation tools to validate designs under real-world conditions, reducing the risk of design failures that could lead to compliance issues. By running simulations on stress, strain, temperature, and fluid dynamics, manufacturers can ensure that their devices meet the performance and safety standards set by regulatory authorities.

Another significant benefit of SOLIDWORKS in medical device manufacturing is its ability to facilitate collaboration among different teams. Engineers, designers, and regulatory experts can work together on the same platform, ensuring that all requirements are met throughout the development process. This collaborative approach ensures that compliance is maintained at every stage, from the initial design to the final production run.

In conclusion, SOLIDWORKS helps medical device manufacturers achieve regulatory compliance by providing the tools needed for documentation, simulation, and collaboration. By ensuring that devices meet stringent safety and performance standards, SOLIDWORKS accelerates the development of medical devices while maintaining the necessary compliance required by the industry.