In the rapidly evolving world of manufacturing, paper-based 2D drawings are becoming relics of the past. SOLIDWORKS Model-Based Definition (MBD) is spearheading this transformation by allowing engineers to embed dimensions, tolerances, and manufacturing instructions directly into 3D models. Going drawing less isn’t just a trend; it’s a strategic shift toward leaner, more agile production workflows.

MBD lets you define, organize, and publish 3D Product Manufacturing Information (PMI) such as GD&T, surface finishes, datums, and material specs within the model itself. This single source of truth ensures all stakeholders access the latest data, reducing risks associated with version mismatches or misinterpretation. It also eliminates the time-consuming process of creating and updating 2D drawings.

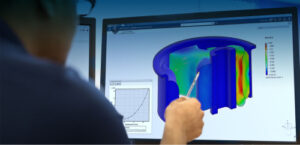

One of the key advantages of going drawingless is better communication across teams. With SOLIDWORKS MBD, machinists, quality inspectors, and assembly workers can visualize the exact requirements in 3D. The annotations appear contextually, linked to the relevant surfaces, which eliminates ambiguity and boosts production accuracy.

Moreover, SOLIDWORKS MBD supports industry standards like MIL-STD-31000, ASME Y14.41, and ISO 16792, ensuring seamless integration into global supply chains. This means your drawingless models are not only readable but fully compliant with critical documentation requirements.

The benefits extend into digital transformation initiatives. Going drawingless allows integration with downstream systems like ERP and MES, helping companies improve traceability, reduce documentation costs, and support sustainability efforts by going paperless. According to a survey by Lifecycle Insights, companies using MBD saw a 20–50% reduction in documentation and manufacturing errors.

In a world where speed, accuracy, and clarity define success, adopting SOLIDWORKS MBD to go drawingless is more than a technological upgrade—it’s a cultural shift. It brings engineering, manufacturing, and quality assurance onto the same page, quite literally, by turning your 3D model into the master document.