Manufacturing industrial machinery involves transforming complex designs into functional, high-quality products. The manufacturing process can be time-consuming and prone to errors if not properly optimized. SOLIDWORKS CAM (Computer-Aided Manufacturing) streamlines this process by integrating design and manufacturing workflows, providing manufacturers with tools to automate machining operations, reduce production time, and minimize errors in the final product.

SOLIDWORKS CAM seamlessly integrates with the SOLIDWORKS design environment, allowing manufacturers to move from design to manufacturing without the need for separate software. This integration ensures that design intent is preserved throughout the entire process, reducing the risk of errors that might occur when transferring data between different platforms. Engineers and machinists can work from a single 3D model, ensuring that the design is accurately translated into the final product.

One of the key benefits of using SOLIDWORKS CAM in industrial machinery manufacturing is its ability to automate machining operations. The software can automatically generate toolpaths for CNC machines based on the 3D model of the part. This reduces the need for manual intervention and speeds up the manufacturing process. For example, when producing a part for an industrial gearbox, SOLIDWORKS CAM can automatically generate the optimal toolpath for cutting, drilling, and finishing the part, ensuring that it meets the required specifications.

SOLIDWORKS CAM also supports a wide range of manufacturing processes, including milling, turning, and multi-axis machining. This versatility is particularly important in the industrial machinery sector, where a wide variety of parts and components need to be produced. The software is designed to handle complex geometries, such as those found in industrial machinery components like gears, shafts, and housings. By automating the toolpath generation for these parts, SOLIDWORKS CAM helps reduce setup times, improve machining accuracy, and increase overall productivity.

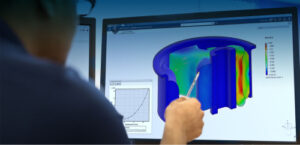

Additionally, SOLIDWORKS CAM includes tools for verifying the toolpaths before the actual machining begins. This virtual simulation allows manufacturers to check for collisions, errors, and inefficiencies in the machining process, minimizing the risk of costly mistakes on the shop floor. By running a simulation of the machining process, engineers can ensure that the part is produced correctly the first time, reducing material waste and improving cost efficiency.

Another key advantage of SOLIDWORKS CAM is its ability to optimize tool usage and machining strategies. The software helps manufacturers select the most efficient cutting tools and machining operations based on the specific requirements of the part. This not only improves machining time but also extends the lifespan of the tools, reducing maintenance costs and minimizing downtime.

In conclusion, SOLIDWORKS CAM enhances the manufacturing of industrial machinery by automating machining operations, improving design-to-manufacturing integration, and reducing the risk of errors. By streamlining the manufacturing process, SOLIDWORKS CAM enables manufacturers to produce high-quality, cost-effective machinery components in less time, improving efficiency and competitiveness in the industrial machinery sector.