Maintenance and lifecycle management are essential aspects of energy plant operation. To maximize the lifespan of equipment and minimize downtime, energy plant operators must be able to monitor, maintain, and repair components efficiently. SOLIDWORKS offers powerful tools for enhancing the maintenance process, providing engineers and plant operators with accurate digital models, predictive maintenance simulations, and easy access to design data throughout the plant’s lifecycle.

One of the primary benefits of SOLIDWORKS in lifecycle management is its ability to create detailed 3D models of all plant components. These models can be used to create comprehensive maintenance manuals and digital twins of the plant, allowing operators to monitor the condition of components in real time. With accurate digital representations of pumps, turbines, boilers, and other equipment, operators can easily identify wear and tear, monitor operating conditions, and plan maintenance activities more effectively.

For example, when planning a maintenance shutdown, operators can use SOLIDWORKS models to identify components that require attention and assess the time and resources needed for repairs. By visualizing the plant in 3D, maintenance teams can plan the most efficient route to access parts, minimizing downtime and improving operational efficiency.

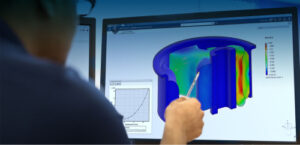

SOLIDWORKS also helps with predictive maintenance by simulating how components will degrade over time. Engineers can use the software to model the wear and tear on components such as turbines, pipes, and electrical systems based on operational conditions such as temperature, pressure, and vibration. This allows them to predict when a component is likely to fail and schedule maintenance accordingly, reducing the risk of unexpected breakdowns and costly repairs.

Moreover, SOLIDWORKS’ integration with other enterprise resource planning (ERP) systems enables plant operators to track spare parts inventory, schedule maintenance tasks, and monitor component performance across the entire lifecycle. This digital approach to maintenance ensures that plant operators have up-to-date information on the status of all components, enabling them to make informed decisions and take proactive measures to keep the plant running smoothly.

In conclusion, SOLIDWORKS enhances the maintenance and lifecycle management of energy plants by providing digital models, predictive maintenance simulations, and real-time monitoring tools. By leveraging these capabilities, plant operators can reduce downtime, extend the lifespan of equipment, and optimize maintenance operations, ultimately improving the efficiency and reliability of energy production.