Industrial Machinery

- Home

- Aerospace

The industrial machinery sector focuses on designing and building complex systems used in manufacturing, automation, and heavy applications. These machines need to be precise, durable, and customizable- making it essential for engineers to use powerful design tools that handle large assemblies, motion analysis, and performance testing

Panshul Technologies is an authorized SOLIDWORKS Reseller for Industrial Machinery Design in Mumbai, Navi Mumbai, Thane, Nashik | Get a Free Demo & Best SOLIDWORKS Price

Industrial Machinery

SOLIDWORKS offers comprehensive solutions to meet the evolving needs of the industrial machinery industry. From creating large assemblies to validating stress, motion, and real-world performance, SOLIDWORKS helps engineers save time, cut costs, and deliver high-performing machines. It simplifies collaboration, reduces rework, and shortens time to market for industrial equipment.

To know more

ABOUT THE PRODUCT book a free demo

How SOLIDWORKS helped these industries

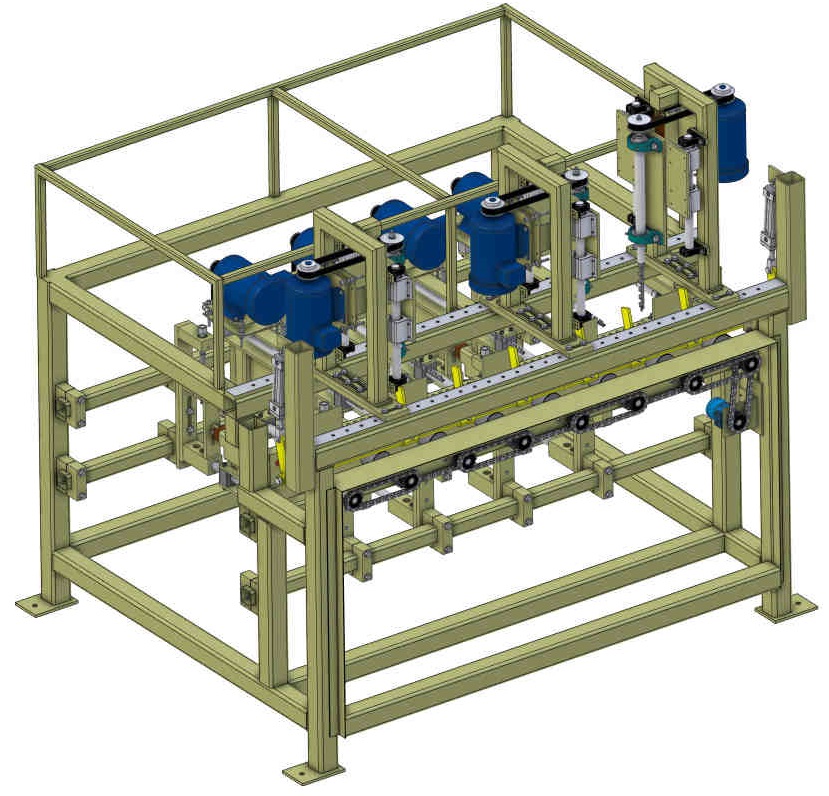

Faster Custom Machine Design

Designers rapidly developed conveyors, automated systems, and heavy equipment using parametric modeling and design automation tools.

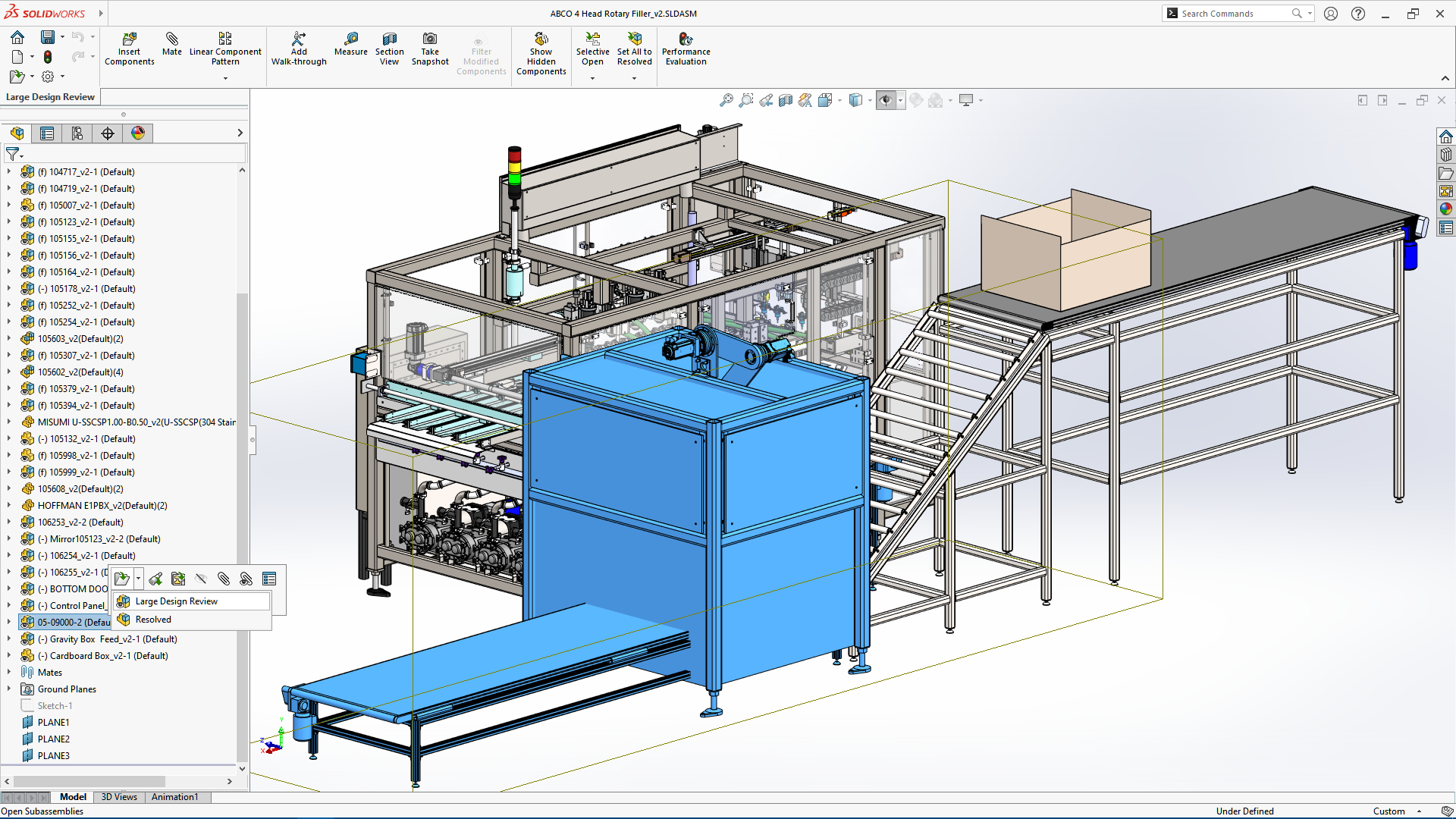

Seamless Large Assembly Handling

Large assemblies with thousands of parts were easily managed, with smooth navigation and performance during design.

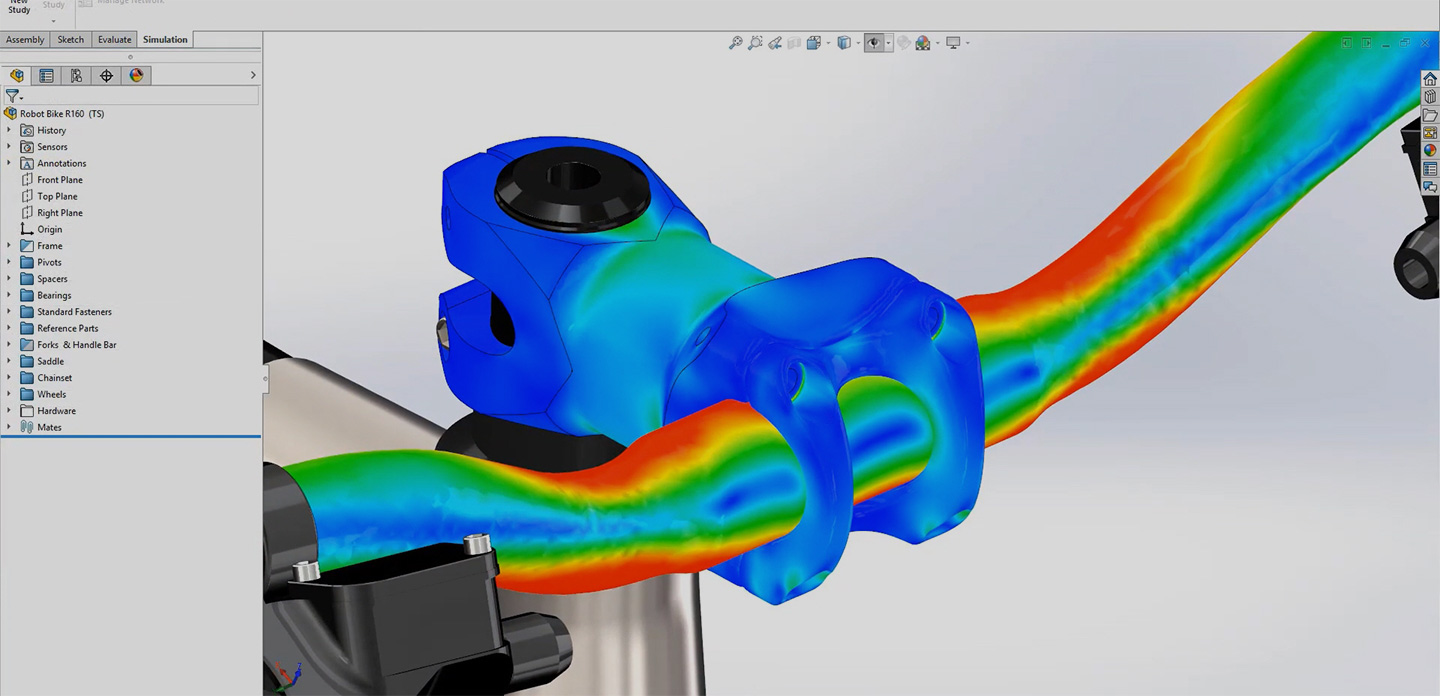

Real-World Motion & Load Simulation

Engineers tested machines under stress, dynamic forces, and motion while maintaining reliable operation before production.

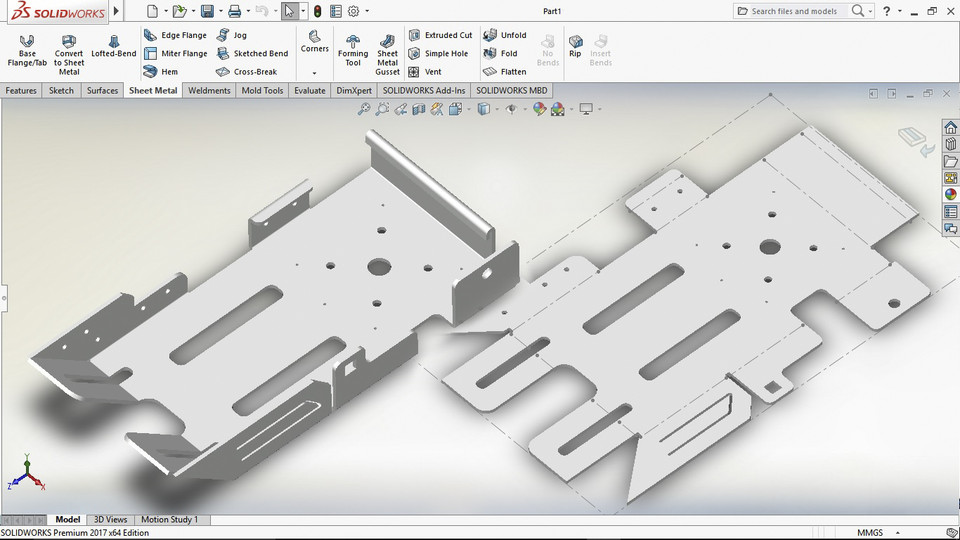

Sheet Metal & Weldment Design

Efficient design of enclosures, brackets, and frames using built-in tools tailored for structural and sheet metal components.

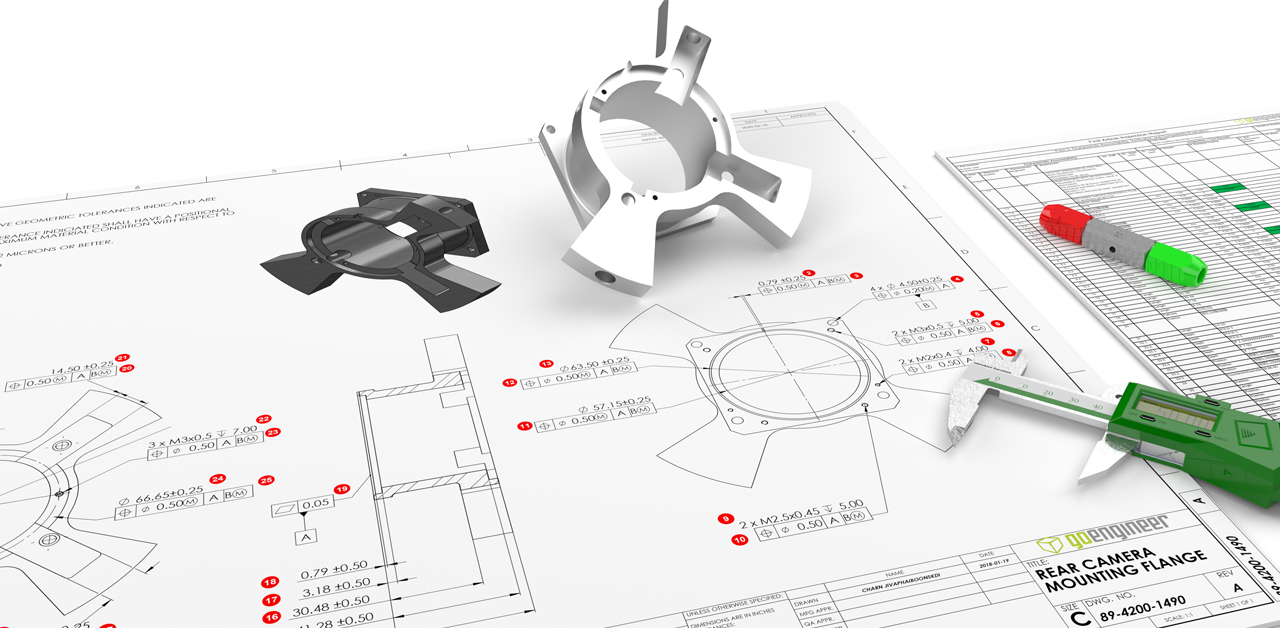

Accurate BOMs & Drawings

Quick generation of exploded views, BOMs, and 2D drawings helped reduce shop floor errors and speed up manufacturing.

Quicker Design Reuse

Design templates and configuration tools enabled companies to quickly replicate and customize machinery designs

Related Products

SOLIDWORKS Premium

Benefits:

• Build large assemblies like CNC machines or conveyors.

• Model parts like shafts, gears, and machine frames.

• Design routed systems for fluids, pneumatics, or cables.

SOLIDWORKS Simulation

Benefits:

• Analyse part strength, fatigue, and safety margins.

• Test loads, vibrations, and operational conditions.

• Minimize physical prototyping and design risks.

SOLIDWORKS Motion

Benefits:

• Simulate moving parts like linkages and actuators.

• Detect collisions or performance issues early.

• Optimize motion for precision and speed.

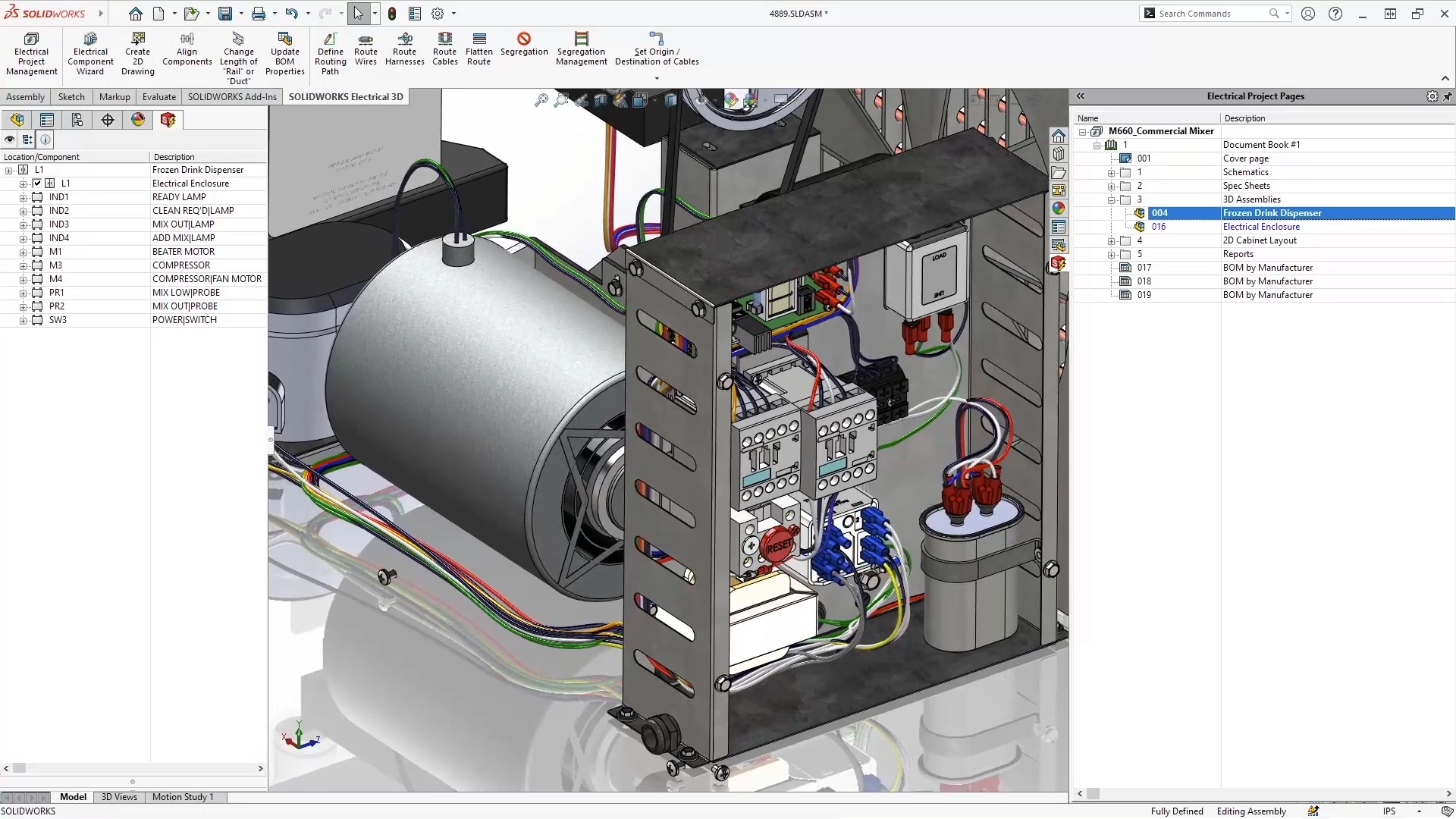

SOLIDWORKS Electrical

Benefits:

• Design control panels and wiring diagrams.

• Sync electrical and mechanical designs.

• Easily integrate sensors, relays, and PLCs.

SOLIDWORKS PDM (Product Data Management)

Benefits:

• Manage CAD files, versions, and revisions.

• Improve team collaboration across departments.

• Ensure document traceability and quick access. after-sales support and service.

SOLIDWORKS Composer

Benefits:

• Create manuals and assembly instructions easily.

• Use 3D models for service and training guides.

• Cut down on technical documentation time.

3DEXPERIENCE Works

Benefits:

• Centralize design, engineering, and production.

• Enable real-time updates and task tracking.

• Collaborate efficiently across clients or vendors.