Manufacturing

- Home

- Manufacturing

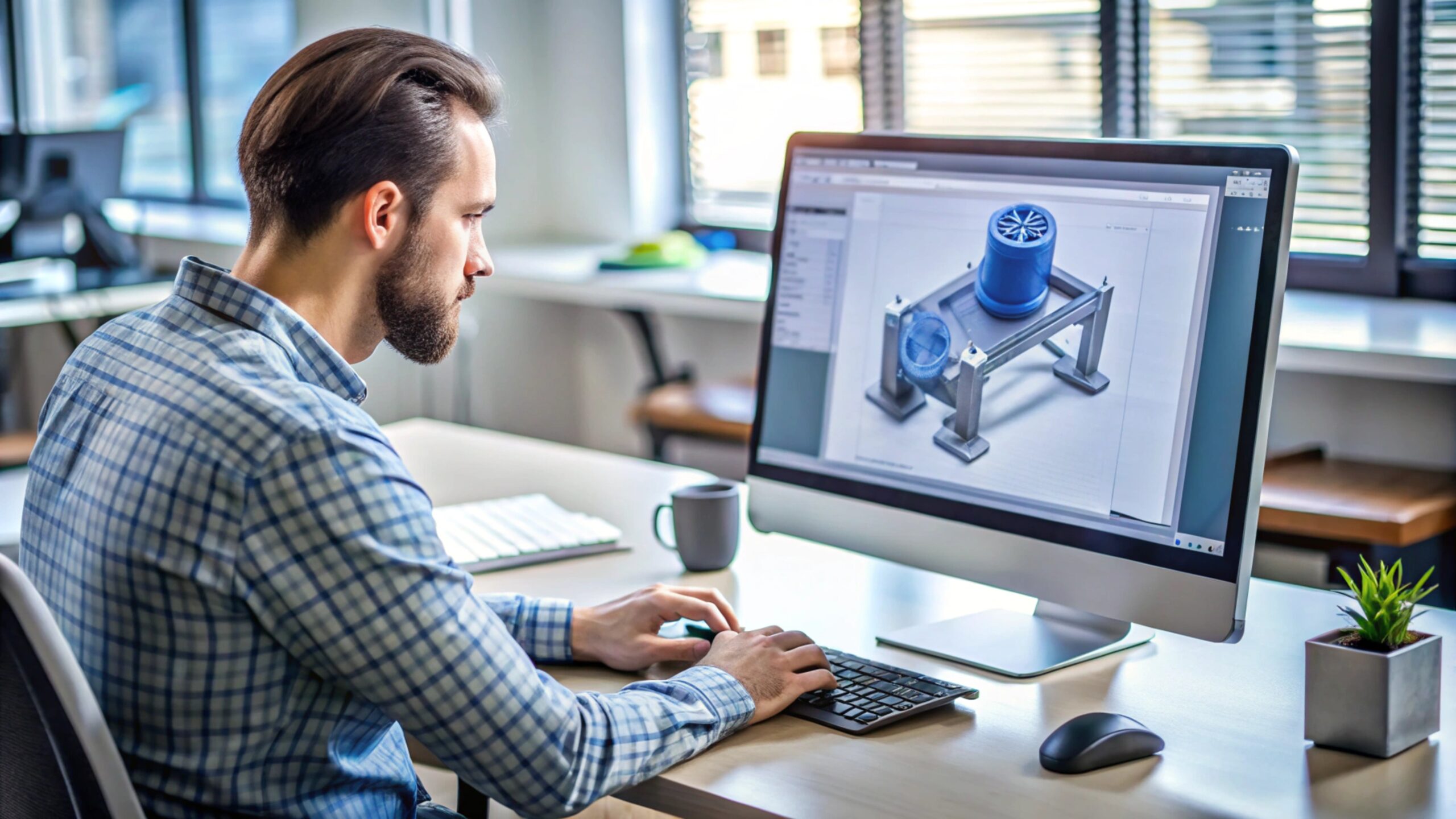

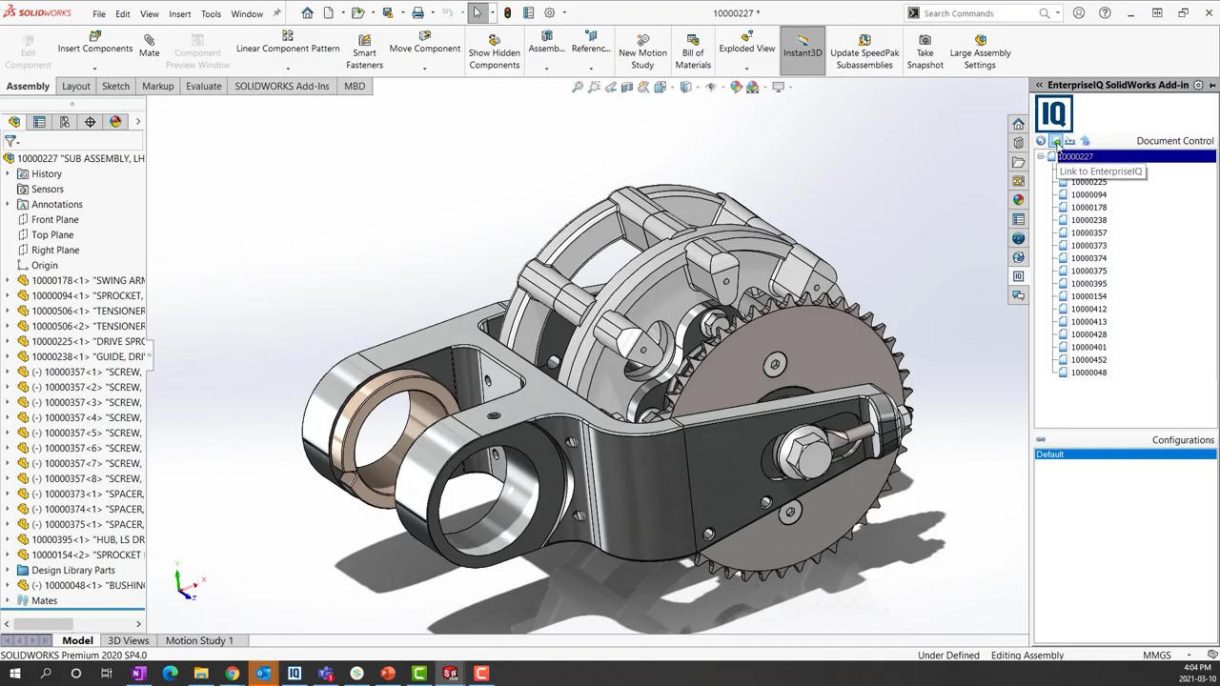

The manufacturing industry drives the global economy by turning raw materials into finished products with machines, human effort, and innovation. It stretches across numerous industries ranging from electronics to heavy machinery where speed, accuracy, and quality are very crucial. Today’s manufacturers need smarter design tools to remain competitive and address changing production requirements.

Panshul Technologies is an authorized SOLIDWORKS Reseller for Manufacturing Design & Automation in Mumbai, Navi Mumbai, Thane, Nashik | Book a Free Demo & Get SOLIDWORKS at the Best Price

Manufacturing Sector

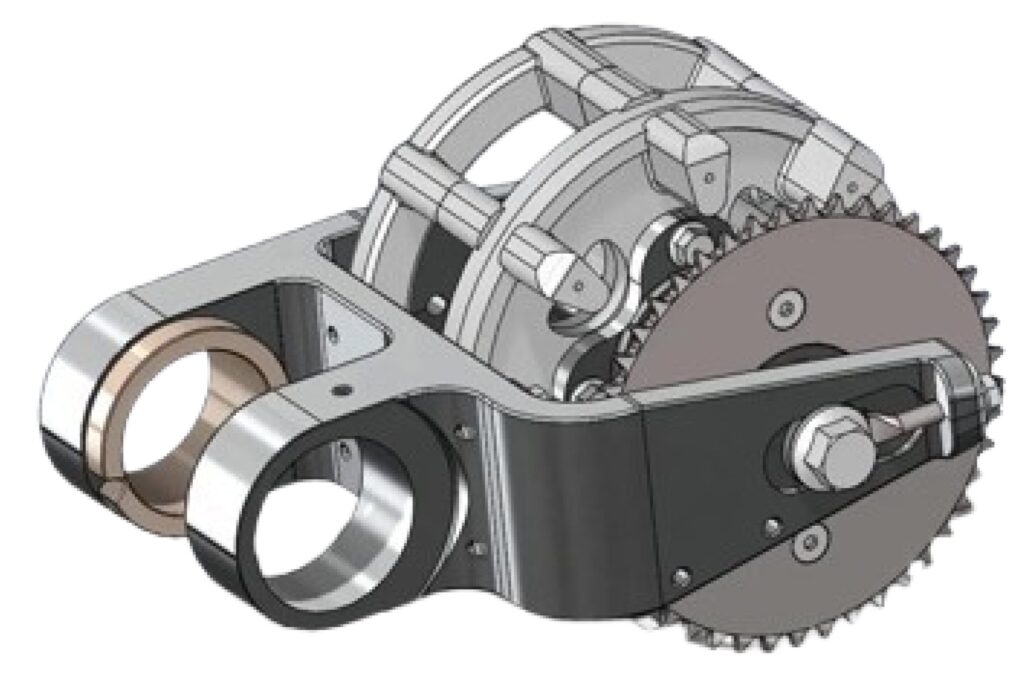

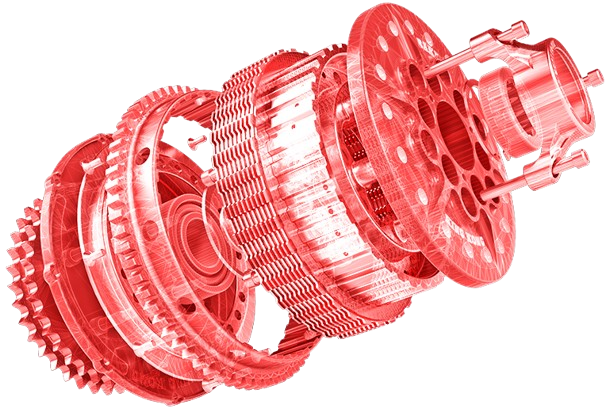

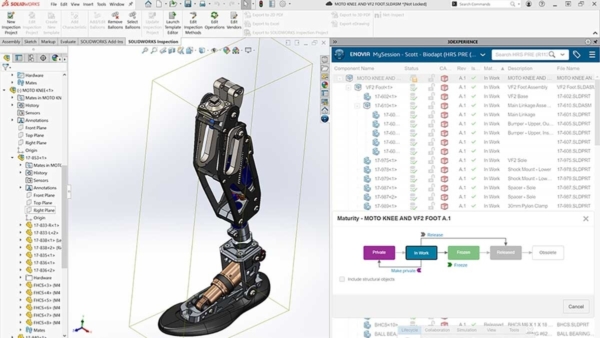

SOLIDWORKS brings powerful solutions for every stage of the product lifecycle, helping equipment manufacturers and machine manufacturing companies move from concept to production with speed and accuracy. Engineers use SOLIDWORKS to model complex parts, test functionality, and optimize performance before hitting the shop floor. With simulation, electrical design, CAM integration, and technical documentation tools, SOLIDWORKS simplifies operations, reduces rework, and drives faster product launches. SOLIDWORKS brings powerful solutions for every stage of the product lifecycle, helping equipment manufacturers and machine manufacturing companies move from concept to production with speed and accuracy. Engineers use SOLIDWORKS to model complex parts, test functionality, and optimize performance before hitting the shop floor. With simulation, electrical design, CAM integration, and technical documentation tools, SOLIDWORKS simplifies operations, reduces rework, and drives faster product launches.

To know more

ABOUT THE PRODUCT book a free demo

How SOLIDWORKS helped this industries

End-to-End Product Development

Created a connected digital workflow from concept through production—reducing iterations and accelerating timelines.

Parametric Design for Custom Manufacturing

Enabled fast updates to jigs, fixtures, and parts with parametric CAD models ideal for high-mix, low-volume manufacturing.

Integrated CAM for Faster CNC Programming

Generated toolpaths directly from CAD, reducing setup time and ensuring accurate machining.

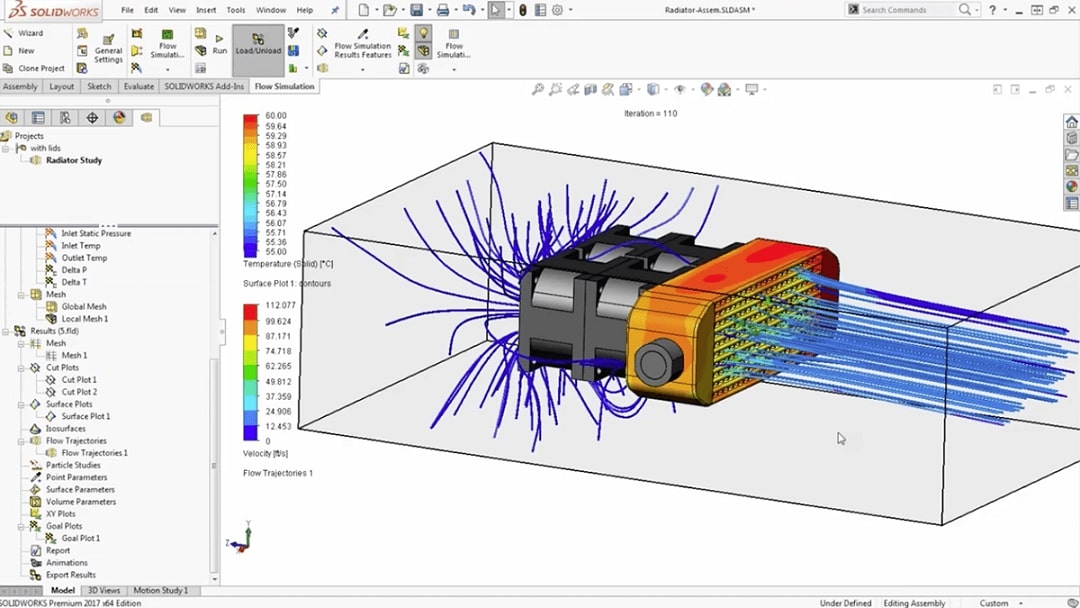

Performance Simulation Before Production

Validated strength, fatigue, and thermal loads to reduce the need for costly physical prototypes.

Tools for Sheet Metal, Molds, and Weldments

Designed complex tooling and fabrication structures efficiently using built-in manufacturing toolsets.

Automated BOMs and Shop Floor Docs

Quickly produced drawings, Bills of Materials, and guides to bridge design with production.

Related Products

SOLIDWORKS Premium

Benefits:

- Design everything from small parts to full-scale production systems.

- Use routing tools for piping, cabling, and tubing layouts.

- Manage large assemblies for tools, jigs, and factory layouts.

SOLIDWORKS Simulation

Benefits:

- Test for strength, load capacity, and fatigue life.

- Reduce prototyping by validating designs digitally.

- Ensure tools and products perform reliably in production.

SOLIDWORKS CAM

Benefits:

- Automatically generate CNC toolpaths from 3D models.

- Reduce programming time and machining errors.

- Sync CAD and CAM for smoother manufacturing transitions.

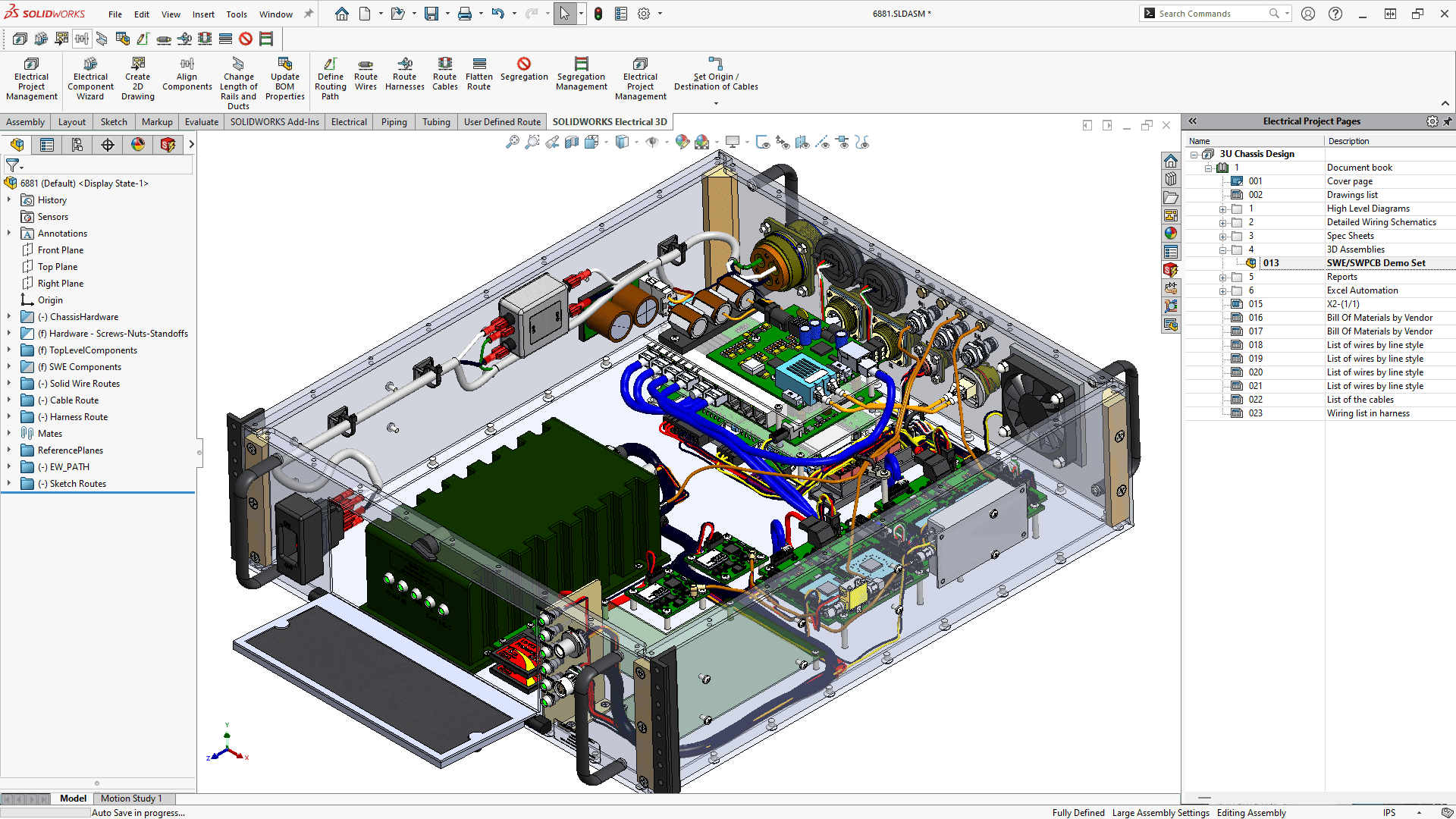

SOLIDWORKS Electrical

Benefits:

- Design wiring, schematics, and control systems.

- Integrate electrical and mechanical designs seamlessly.

- Improve automation and accuracy in manufacturing lines.

SOLIDWORKS PDM (Product Data Management)

Benefits:

- Centralize file storage, version control, and documentation.

- Enable real-time collaboration across teams.

- Avoid outdated files and ensure audit-ready traceability.

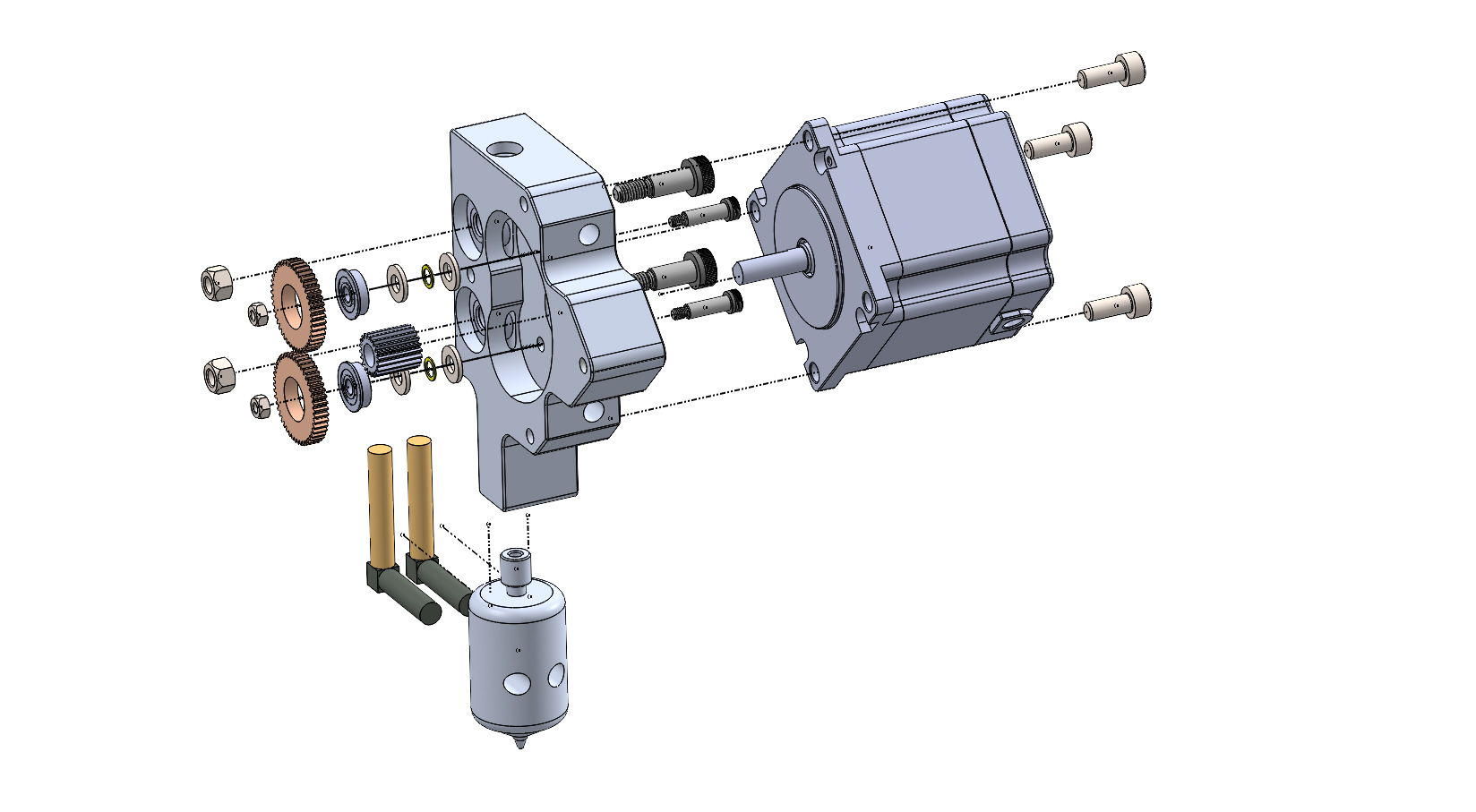

SOLIDWORKS Composer

Benefits:

- Create detailed assembly and service instructions.

- Help teams reduce errors with visual step-by-step guides.

- Speed up onboarding and training with interactive content.

3DEXPERIENCE Works

Benefits:

- Connect design, procurement, and production on the cloud.

- Collaborate with internal teams and suppliers in real time.

- Monitor tasks, deadlines, and revisions with full visibility.