Mould tools & Die

- Home

- Mold tools & Die

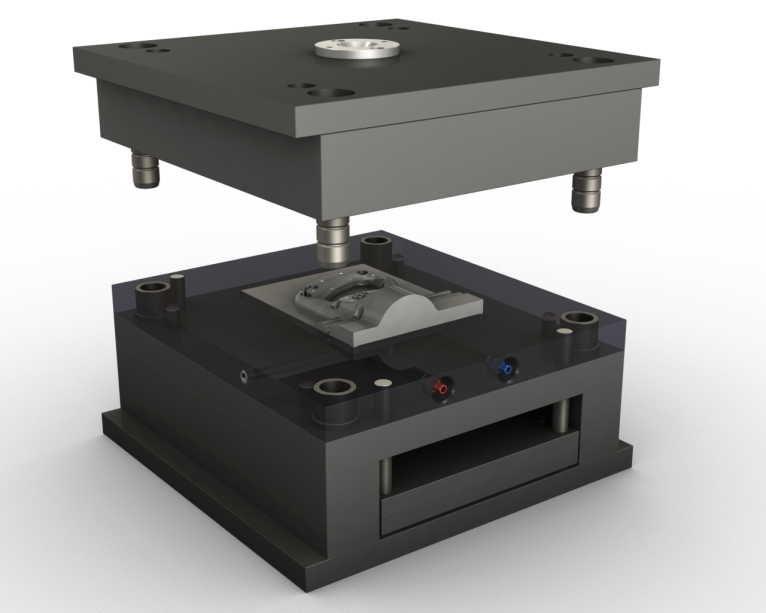

The Mold, tools, and die industry plays a crucial role in manufacturing by enabling mass production with precision, serving as an important component in several products we use daily. These parts have to be highly accurate, durable, and capable of withstanding repeated stress. Toolmakers and mold designers rely on advanced CAD solutions to reduce material waste, speed up prototyping, and ensure tooling integrity.

Panshul Technologies is an authorized SOLIDWORKS Reseller for Mold Tools & Die Design in Mumbai, Navi Mumbai, Thane, Nashik | Book a Free Demo & Get Exclusive SOLIDWORKS Pricing

Mold tools & Die

SOLIDWORKS provides end-to-end design and simulation tools that simplify mold design, tooling validation, and manufacturing documentation. With intelligent features for core&cavity separation, draft analysis, and electrode design, engineers can optimize complex tool geometry, reduce rework, and deliver high-quality molds and dies faster

To know more

ABOUT THE PRODUCT book a free demo

How SOLIDWORKS helped these industries

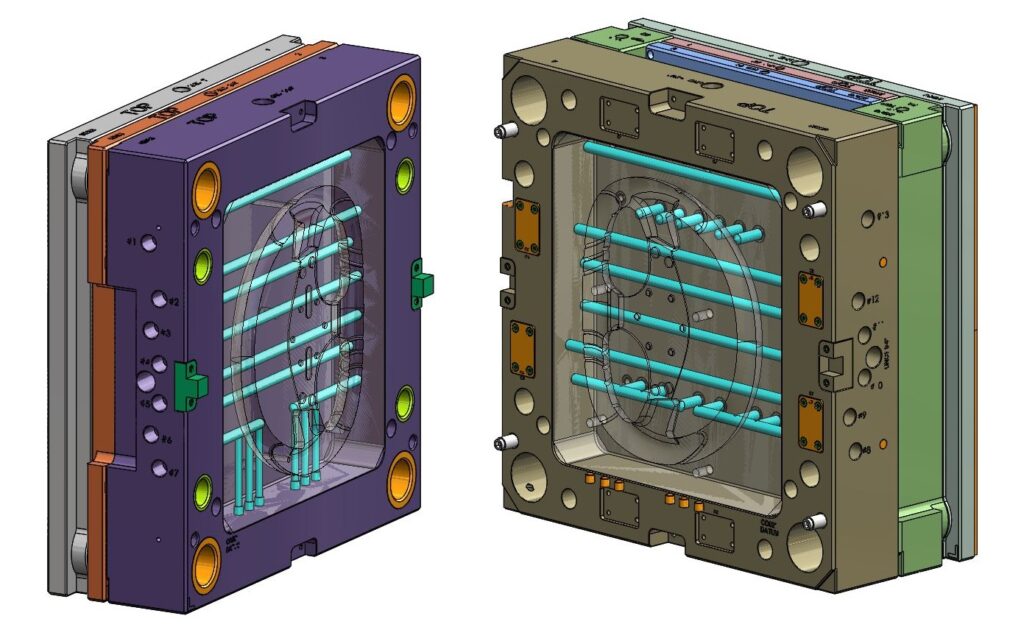

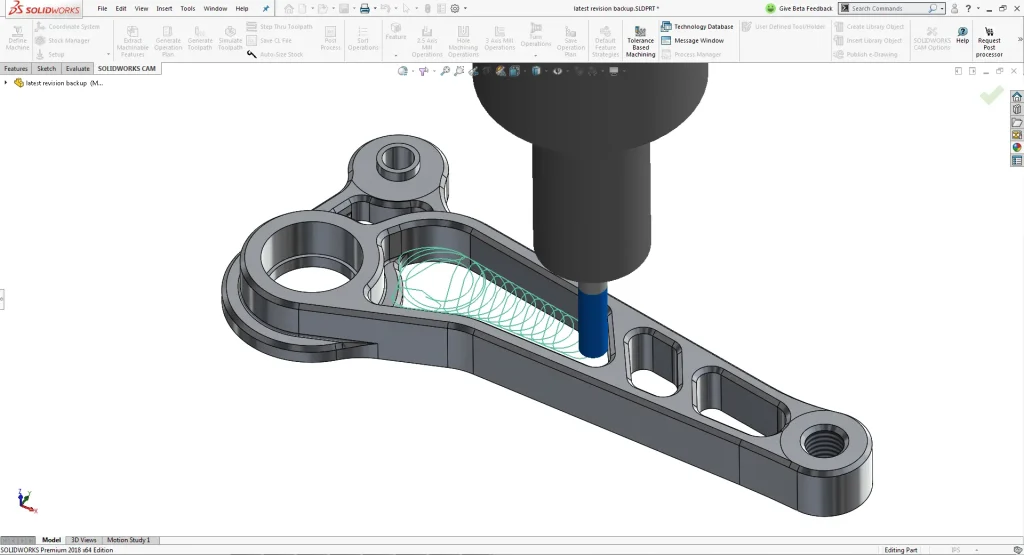

Faster Mold Design with Automation

SOLIDWORKS users cut down design time using automated core/cavity creation and parting line detection tools.

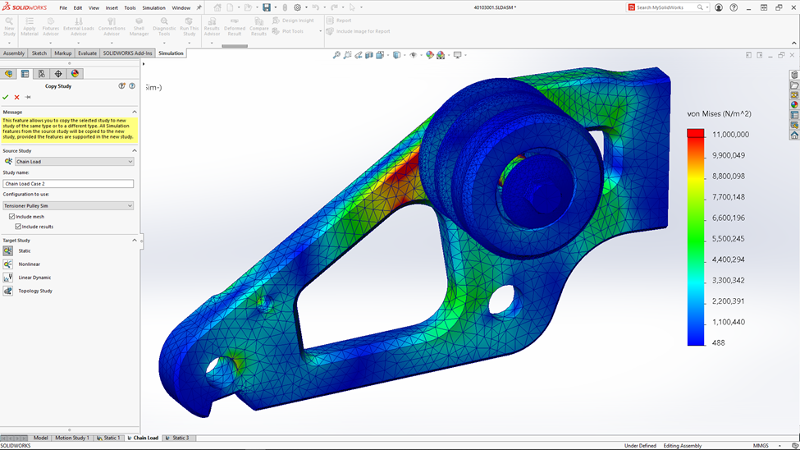

Improved Tool Durability with Simulation

Engineers tested molds and dies under operating stress to ensure they perform reliably and resist deformation.

Simplified Manufacturing Prep

Users generated precise machining instructions and electrode designs directly from 3D models, improving efficiency.

Draft and Undercut Analysis

Built-in tools flagged manufacturing issues early, saving time during mold release and die-cutting stages.

Streamlined Design Changes

Design revisions were faster with parametric features and file associativity, ensuring consistent updates.

Reduced Scrap with Better Fit and Finish

Dimensional checks and tolerance analysis tools helped deliver perfect part fits and fewer rejections

Related Products

SOLIDWORKS Premium

Benefits:

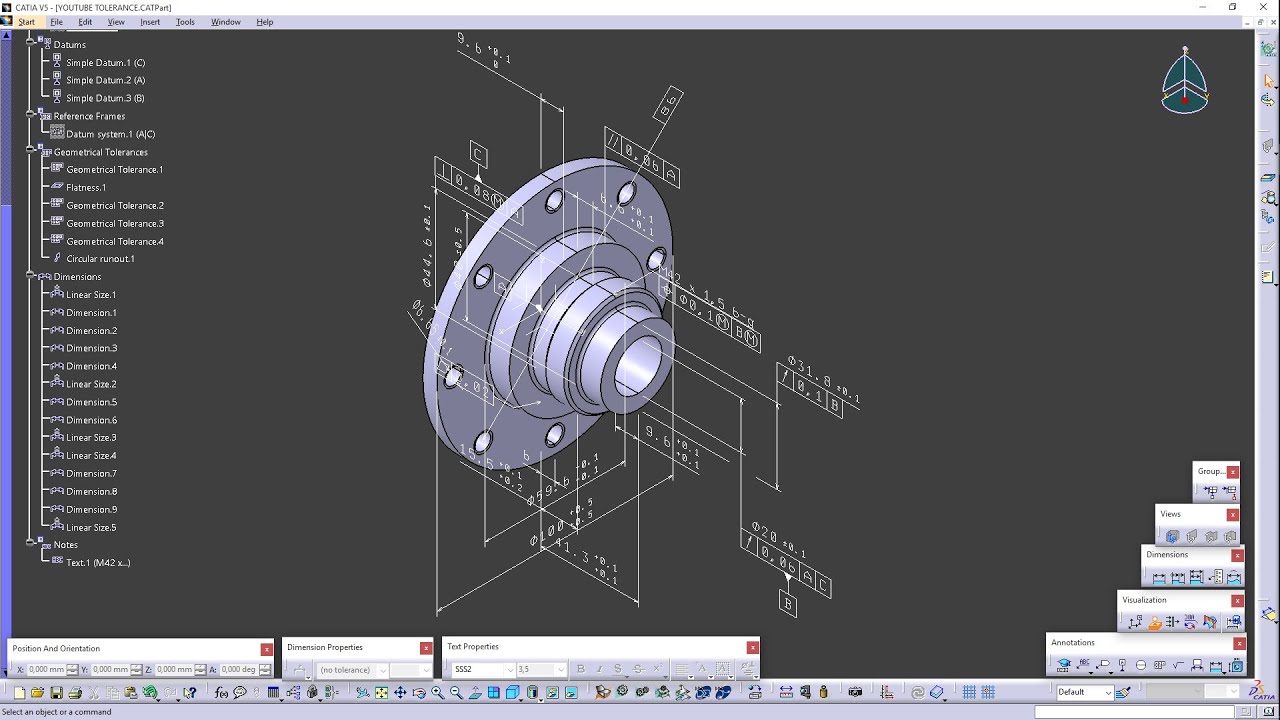

• Design molds, tooling components, and complex dies.

• Use surfacing tools for intricate geometry creation.

• Access draft, undercut, and parting line analysis tools.

SOLIDWORKS Plastics

Benefits:

• Simulate plastic flow, fill, cooling, and warpage.

• Prevent defects like air traps and short shots.

• Optimize gate location and cooling channel design.

SOLIDWORKS Simulation

Benefits:

• Analyse die strength, wear, and thermal performance.

• Predict deformation under high-pressure loads.

• Improve durability of tooling under repeated use.

SOLIDWORKS Electrical

Benefits:

• Design control units for injection molding systems.

• Sync control circuits with mechanical design.

• Ensure proper sensor, relay, and actuator connections.

SOLIDWORKS PDM (Product Data Management)

Benefits:

• Track file versions for dies and tool components.

• Manage revisions during frequent tooling updates.

• Securely store and share documentation with teams.

SOLIDWORKS Composer

Benefits:

• Create mold setup, usage, and maintenance guides.

• Use 3D visuals for operator training and support.

• Reduce time spent on service documentation.

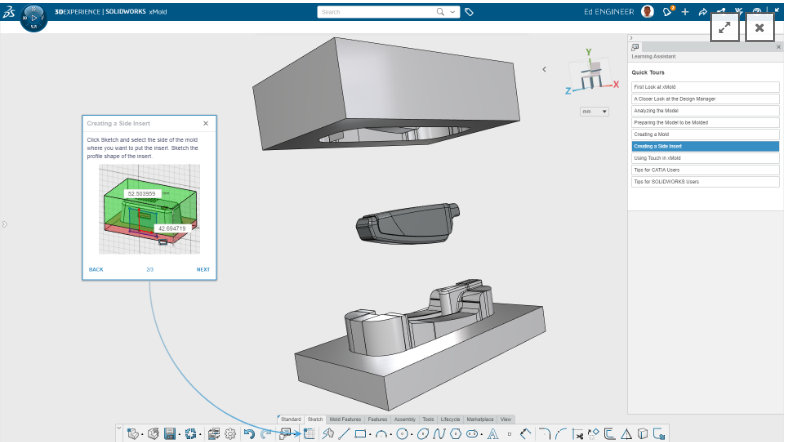

3DEXPERIENCE Works

Benefits:

• Collaborate with mold makers, machinists, and OEMs.

• Centralize design, simulation, and production data.

• Track issues and approvals on one connected platform