The manufacturing of oil and gas equipment is a highly specialized process that demands precision, efficiency, and reliability. Components such as pipes, valves, pressure vessels, and drilling equipment must meet strict quality standards to ensure their performance in high-pressure, high-temperature environments. SOLIDWORKS CAM is an essential tool in automating the manufacturing process, improving efficiency, and ensuring high-quality production of oil and gas equipment.

SOLIDWORKS CAM seamlessly integrates with the 3D CAD model, allowing manufacturers to generate CNC toolpaths directly from the design. This eliminates the need for manual programming and reduces the potential for human error during the manufacturing process. Given the complexity of oil and gas equipment, where even minor deviations can lead to catastrophic failures, automating this process ensures that parts are produced accurately and consistently, minimizing the risk of defects.

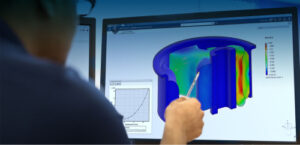

One of the key benefits of SOLIDWORKS CAM is its ability to simulate the machining process before it is executed. This simulation allows engineers to visualize how the CNC machines will cut, shape, and drill the material, providing an opportunity to detect potential issues, such as tool collisions or inefficient tool paths. By identifying and addressing these problems early, manufacturers can avoid costly mistakes and delays during production.

In addition to simulation, SOLIDWORKS CAM also optimizes the use of materials during the manufacturing process. In the oil and gas industry, where high-performance materials like stainless steel or alloy are often used, reducing material waste is essential to keeping production costs manageable. By automatically generating the most efficient tool paths, SOLIDWORKS CAM ensures that manufacturers make the best use of the raw materials available, reducing waste and increasing overall cost-efficiency.

Another significant advantage of SOLIDWORKS CAM is its ability to handle complex geometries. Many oil and gas components, such as valves, pumps, and specialized fittings, feature intricate designs that require precise machining. SOLIDWORKS CAM’s advanced toolpath strategies ensure that even these complex geometries are manufactured with the highest accuracy.

By integrating SOLIDWORKS CAM into the manufacturing process, companies can streamline production, reduce errors, and improve the quality of their oil and gas equipment. This results in faster turnaround times, lower production costs, and higher-quality products that meet the stringent standards of the oil and gas industry.