In the medical equipment industry, the design of medical devices must adhere to the highest standards of safety, reliability, and performance. Whether developing implants, diagnostic machines, or surgical instruments, engineers need to ensure that their designs can withstand extreme conditions while maintaining patient safety. SOLIDWORKS Simulation plays a crucial role in helping manufacturers optimize their designs by providing advanced tools to simulate real-world conditions and predict performance outcomes before manufacturing begins.

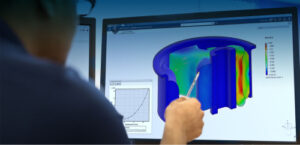

SOLIDWORKS Simulation enables engineers to analyze various forces and stresses that medical devices will face in real-world applications. For example, when designing implants like hip replacements, the materials used must be able to endure repeated mechanical stresses without causing harm to the patient. By running simulations, engineers can identify weak points in the design and adjust them to ensure the device will perform reliably throughout its lifecycle.

Thermal simulations are equally important, especially in devices like pacemakers or MRI machines, where managing heat distribution is critical for both performance and safety. SOLIDWORKS allows engineers to simulate how heat will transfer through the device, ensuring that the components do not overheat or malfunction. Additionally, engineers can use fluid flow simulations to test devices like ventilators or drug delivery systems to ensure that fluids are properly delivered and controlled.

The ability to run virtual simulations in SOLIDWORKS also reduces the need for physical prototypes, which can be costly and time-consuming. By testing designs virtually, manufacturers can significantly shorten the product development cycle and reduce costs while ensuring the device meets all necessary safety standards. This is particularly crucial in the medical industry, where regulatory approval and safety certifications are mandatory.

In conclusion, SOLIDWORKS Simulation allows medical equipment manufacturers to optimize designs by testing them virtually under real-world conditions. By addressing potential issues early in the design process, engineers can create high-quality, reliable devices that meet the stringent safety standards required for medical use.