Energy plant design and construction involve complex processes that require careful planning, especially when it comes to layout and space management. The arrangement of equipment, pipes, and electrical systems must be precise to ensure smooth operation and easy maintenance. SOLIDWORKS plays a crucial role in streamlining this process, offering advanced tools for designing plant layouts that maximize space, enhance operational flow, and reduce the risk of errors during construction.

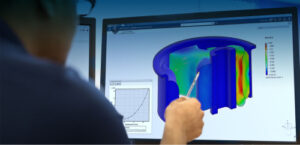

One of the key features of SOLIDWORKS is its ability to create accurate 3D models of energy plant facilities. Engineers can use the software to model the entire plant, from the power generation equipment to the support structures and auxiliary systems. By visualizing the entire facility in 3D, engineers can plan the placement of critical components with greater precision, ensuring that there is enough space for maintenance access, piping, and wiring, while avoiding potential clashes between systems. This holistic approach to design reduces the risk of costly changes during construction and helps ensure that the plant operates efficiently from day one.

For instance, when designing the layout of a thermal power plant, engineers need to consider how the boiler, turbine, condenser, and other systems will be arranged to ensure proper flow and cooling. SOLIDWORKS allows designers to create a virtual plant environment, simulating how the systems will interact with each other and testing different configurations. This helps to identify the most space-efficient layout, improving workflow and minimizing potential downtime during plant operation.

Moreover, SOLIDWORKS provides tools for piping and instrumentation design (P&ID) that allow engineers to design the entire network of pipes, valves, and fittings in a plant. These tools integrate seamlessly with 3D models, allowing engineers to design and test piping systems in the virtual environment before construction begins. By simulating fluid flow and pressure in the pipes, engineers can identify potential bottlenecks or weak points, ensuring that the plant operates smoothly and efficiently.

In addition to optimizing space and flow, SOLIDWORKS enables energy plant designers to ensure compliance with safety regulations. The software’s simulation tools allow engineers to test for safety hazards, such as heat buildup, fluid leaks, or structural failures. For example, engineers can simulate how heat will be distributed across a cooling tower or how a fire suppression system will respond in case of an emergency. By running these tests virtually, engineers can improve safety and ensure that the plant meets industry standards.

In conclusion, SOLIDWORKS simplifies the complex process of energy plant layout and space management by providing advanced 3D modeling, simulation, and collaboration tools. These features help engineers optimize the placement of components, streamline plant operation, and ensure safety and compliance, ultimately leading to more efficient and cost-effective energy facilities.