SOLIDWORKS SIMULATION

Test your designs under real-world conditions using SOLIDWORKS Simulation to improve product quality and cut costs on prototyping and physical testing.

Why choose SOLIDWORKS?

Dramatically improve product development and manufacturing with SOLIDWORKS software. As the core of the SOLIDWORKS product suite, it supports everything from design to data management—including simulation, cost estimation, manufacturability checks, CAM, and sustainable design. Trusted by engineers worldwide, SOLIDWORKS makes innovation faster and smarter.

- All-in-one solution for end-to-end product development

- Easy to learn and implement

- Reduce designing time

- Reduce Prototyping costs and design errors

SOLIDWORKS SIMULATION

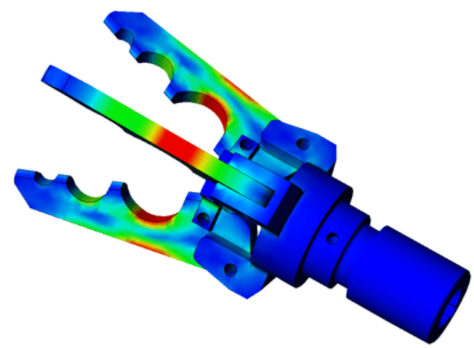

Creating innovative products faster requires accurate simulation of real-world conditions. With enhanced tools like general spring connectors, improved bonding interactions, and faster mesh generation, the 2025 version of SOLIDWORKS Simulation helps predict design behavior early in the process. Seamlessly integrated with SOLIDWORKS 3D CAD, this powerful simulation software enables precise dimensioning, stress testing, and topology optimization—helping you optimize designs while reducing physical prototyping, tooling changes, and overall costs. SOLIDWORKS Simulation software ensures your product can withstand real-world forces during the design stage itself.

Why Choose

SOLIDWORKS for Designing?

-

SOLDIWORKS Premium top 10

features PDF

SOLIDWORKS SIMULATION FEATURES

Advanced Structural Analysis

Ensure the structural integrity and reliability of your designs with advanced structural analysis tools.

Real-World Load Testing

Real-world load testing allows you to virtually simulate how your product will perform under the actual forces

General Spring Connectors

General spring connectors are essential tools in structural and mechanical simulations,

Faster Mesh Generation

Empower your design process with integrated analysis tools that let you simulate, test, and validate your products.

Accurate Simulation Results

Accelerate your simulation workflow with faster mesh generation—an essential step in preparing your models for analysis.

Topology Optimization Tools

Push the boundaries of innovation with topology optimization tools—advanced capabilities that help you create efficient

SIMULATION PACKAGES

Explore and Choose the Best Package that Meets Your Needs.

SOLIDWORKS Simulation Standard

An entry-level analysis tool package that allows designers and engineers to run linear static analysis on individual parts and assemblies, and perform time-based motion studies. If you’re looking to validate basic product strength and movement without leaving the SOLIDWORKS software interface, Simulation Standard is an ideal and cost-effective starting point.

SOLIDWORKS Simulation Professional

Builds upon the capabilities of the Standard package with more advanced testing features. It includes tools for thermal analysis, frequency studies, buckling, fatigue life estimation, and design optimization. This mid-tier SOLIDWORKS Simulation solution is perfect for teams aiming to ensure product durability, performance, and efficiency during early-stage development.

SOLIDWORKS Simulation Premium

It is the most comprehensive simulation suite within the SOLIDWORKS software ecosystem. It adds powerful nonlinear static and dynamic analysis, drop testing, composite material analysis, and large deformation simulations. Ideal for complex engineering challenges, SOLIDWORKS Simulation Premium offers advanced validation for high-performance products, all seamlessly integrated within your SOLIDWORKS 3D CAD workflow.

Advantages of

SOLIDWORKS SIMULATION

An intuitive user interface and extensive analysis capabilities

A unique combination of precision, ease of use, and power

Accurate simulations eliminate the need to build a prototype and test

Ability to study and test parts/assemblies up to large sizes

Overall, quick processes, lesser costs, lighter products

| FEATURES | SIMULATION STANDARD | SIMULATION PROFESSIONAL | SIMULATION PREMIUM |

|---|---|---|---|

| Fully Embedded Analysis | ✓ | ✓ | ✓ |

| Communications | ✓ | ✓ | ✓ |

| Static Stress Analysis | ✓ | ✓ | ✓ |

| Fatigue Analysis | ✓ | ✓ | ✓ |

| Kinematic Motion (Time-Based) | ✓ | ✓ | ✓ |

| Kinematic Motion (Event-Based) | ✓ | ✓ | |

| Submodeling | ✓ | ✓ | |

| 3D Simplification | ✓ | ✓ | |

| Optimization | ✓ | ✓ | |

| Thermal Analysis | ✓ | ✓ | |

| Buckling Analysis | ✓ | ✓ | |

| Frequency Analysis | ✓ | ✓ | |

| Drop Test Analysis | ✓ | ✓ | |

| Pressure Vessel Analysis | ✓ | ||

| Nonlinear Analysis | ✓ | ||

| Plastic Deformation/Residual Stress | ✓ | ||

| Composite Material Analysis | ✓ | ||

| Dynamic Analysis | ✓ | ||

| Forced Vibration Analysis | ✓ |