SOLIDWORKS SIMULATION

Panshul Technologies is an authorized SOLIDWORKS Simulation Software Reseller in Mumbai, Navi Mumbai, Thane, Nashik | Get free Demo of SOLIDWORKS Simulation & best prices.

Improve product performance with real-world testing

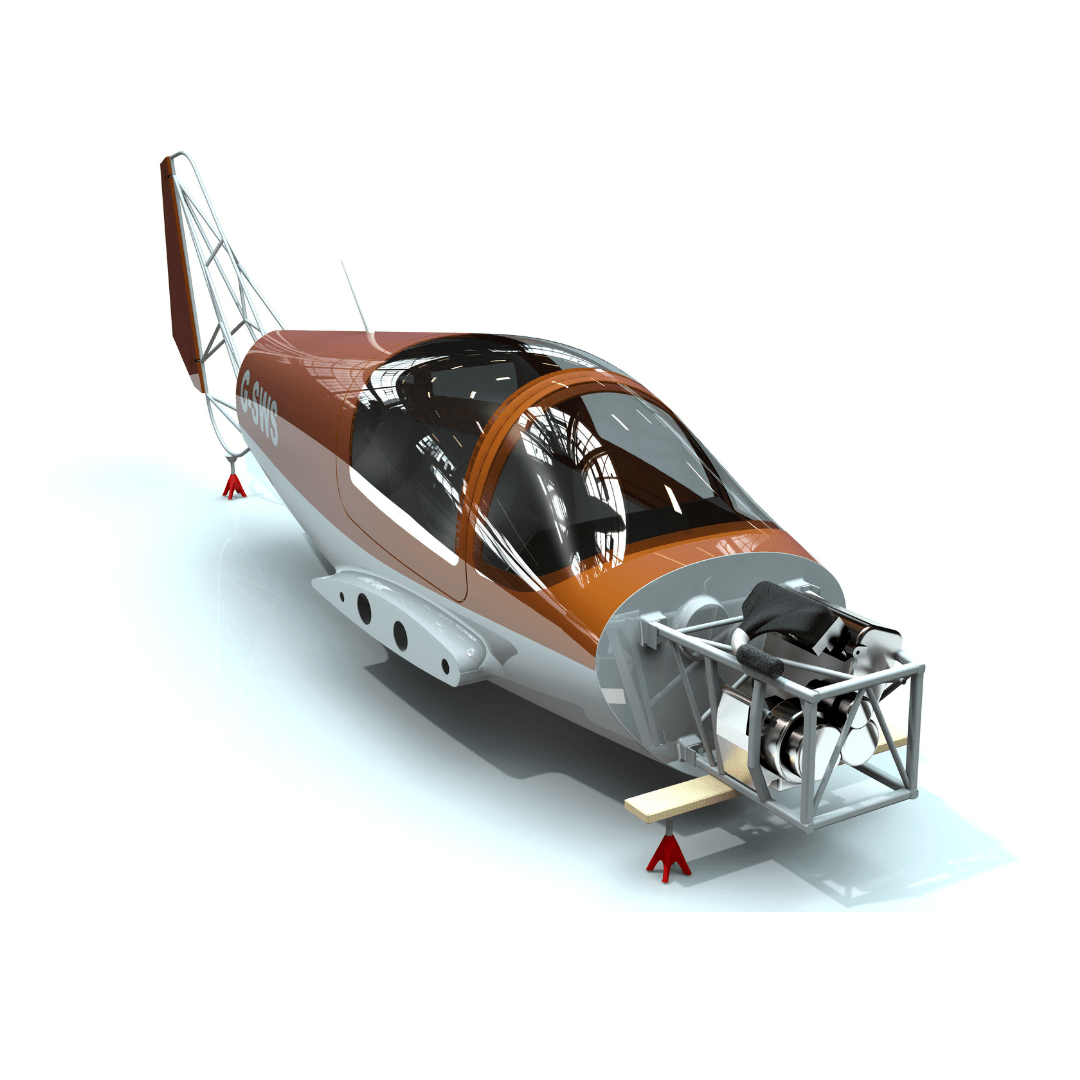

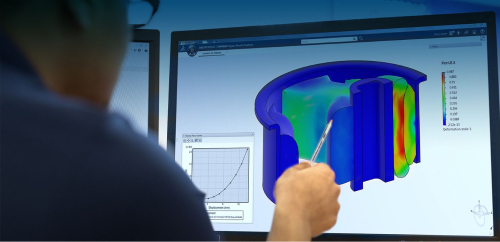

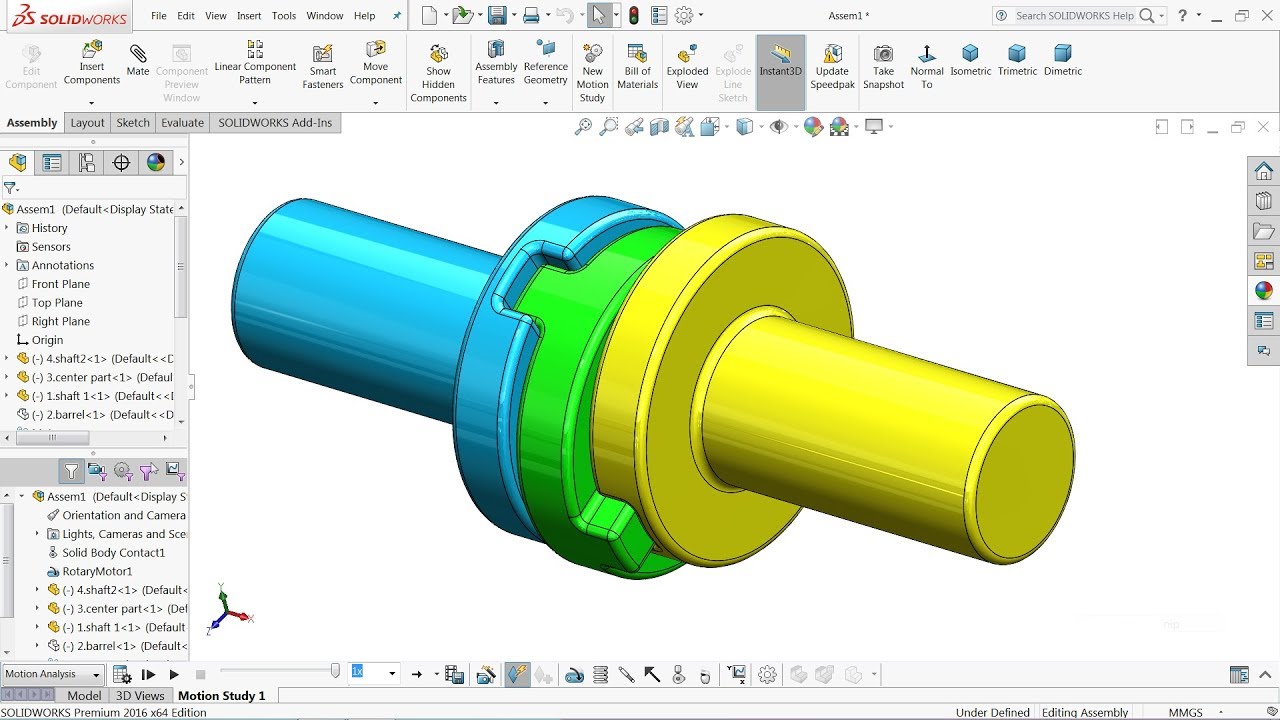

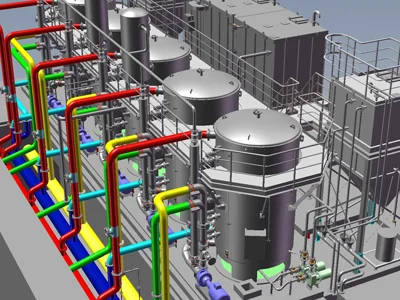

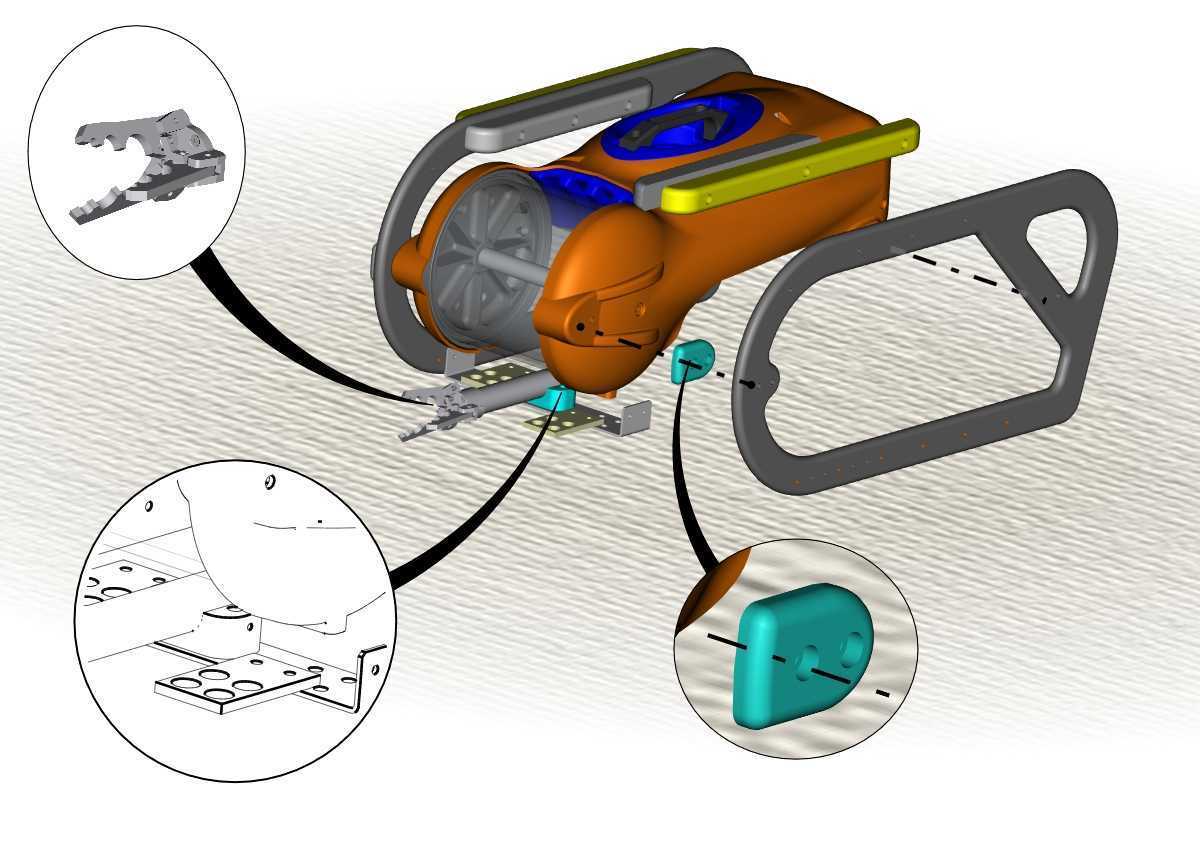

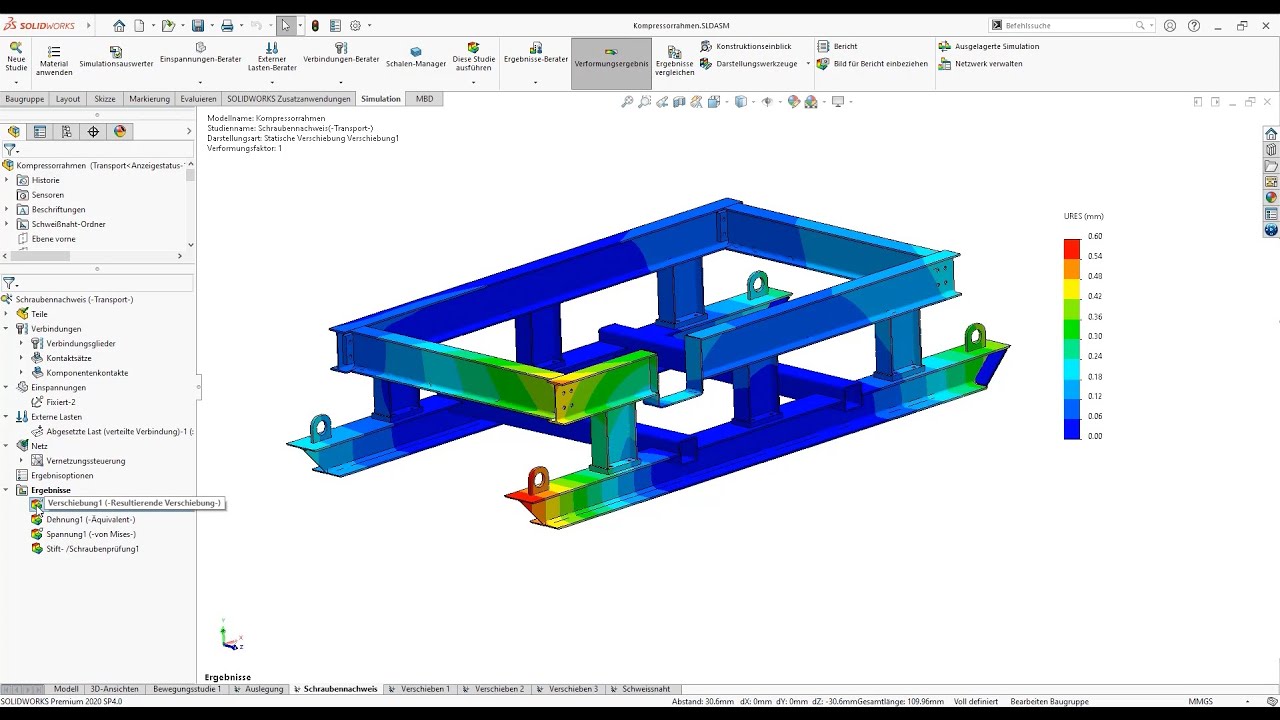

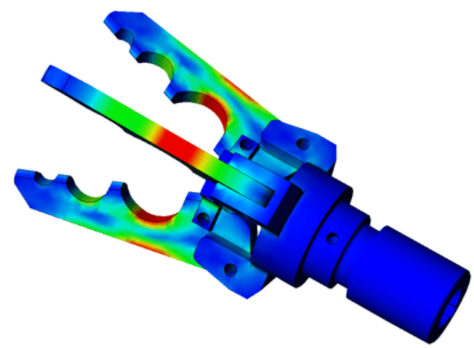

SOLIDWORKS Simulation allows you to virtually test your designs under real-world conditions before a physical prototype is ever made. Whether you’re analyzing stress, motion, heat, or fluid flow, this powerful tool ensures your product performs as expected. Integrated directly with 3D CAD, the simulation tools are easy to access and build for engineers who want quick insights into their design’s strength, durability, and functionality.

If you’re looking for a comprehensive tool that combines CAD design with simulation capabilities in one place, SOLIDWORKS Simulation makes it possible to make smarter decisions right from the design stage.

Why choose SOLIDWORKS?

If you’re looking for a design tool that’s both powerful and easy to use, SOLIDWORKS is a great choice. It doesn’t just help you create 3D models—it also comes with built-in simulation features that let you test how your designs will perform in the real world. With SOLIDWORKS, you can catch problems early, save time, and bring better products to life faster.

Here’s why thousands of engineers’ trust SOLIDWORKS SIMULATION:

- Test products Before production

- Save Time & Costs

- Covers Multiple real time Scenarios

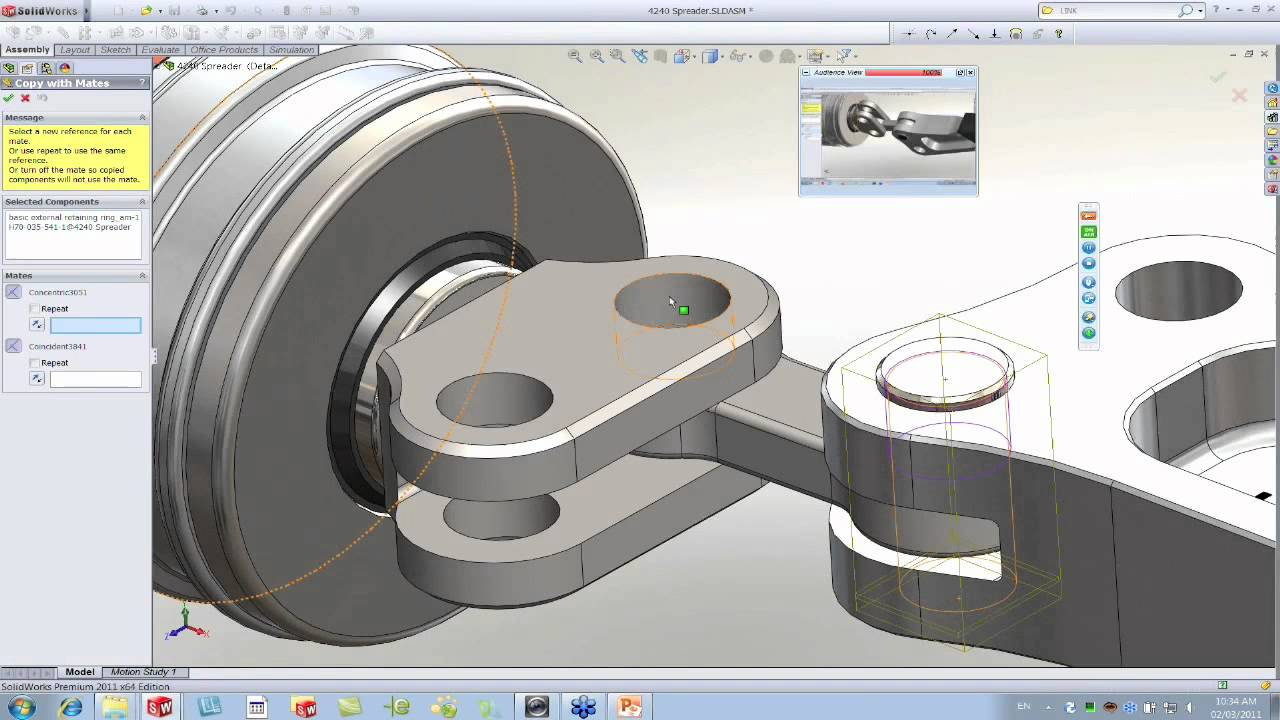

- Improved Team Collaboration

SOLIDWORKS SIMULATION

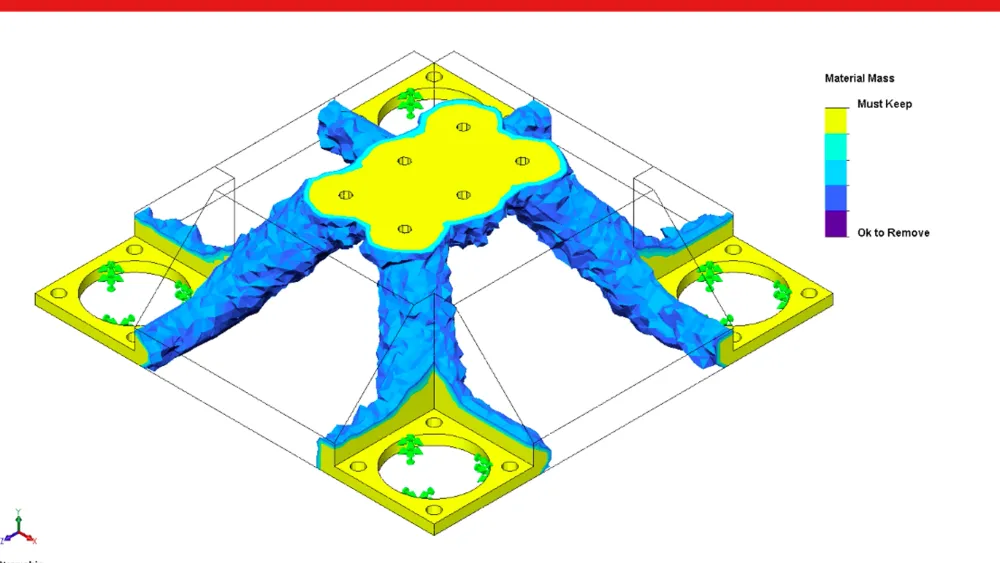

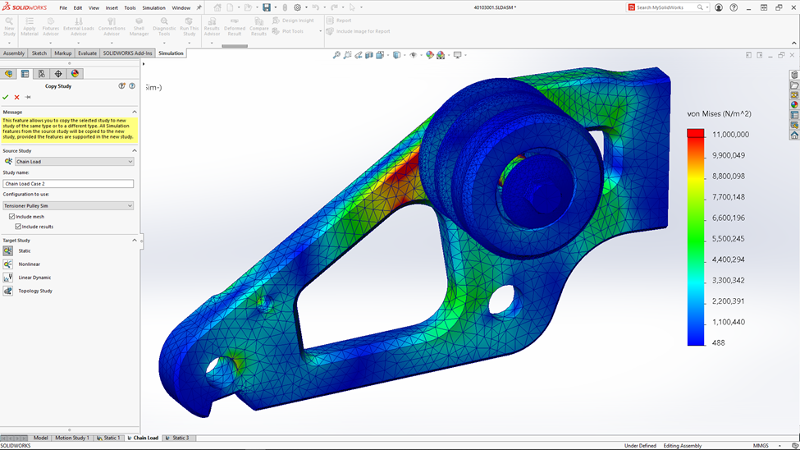

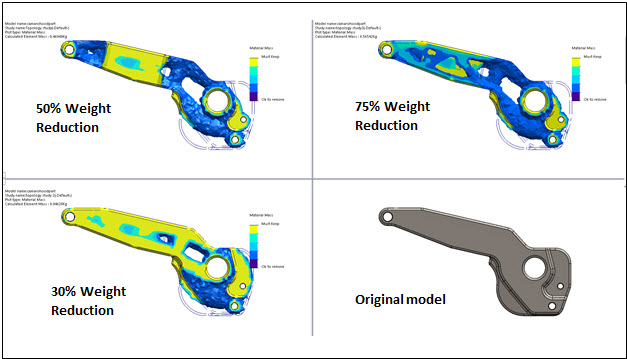

Creating innovative products faster requires accurate simulation of real-world conditions. With enhanced tools like general spring connectors, improved bonding interactions, and faster mesh generation, the 2025 version of SOLIDWORKS Simulation helps predict design behavior early in the process. Seamlessly integrated with SOLIDWORKS 3D CAD, this powerful simulation software enables precise dimensioning, stress testing, and topology optimization—helping you optimize designs while reducing physical prototyping, tooling changes, and overall costs. SOLIDWORKS Simulation software ensures your product can withstand real-world forces during the design stage itself.

What’s New in SOLIDWORKS Simulation 2025

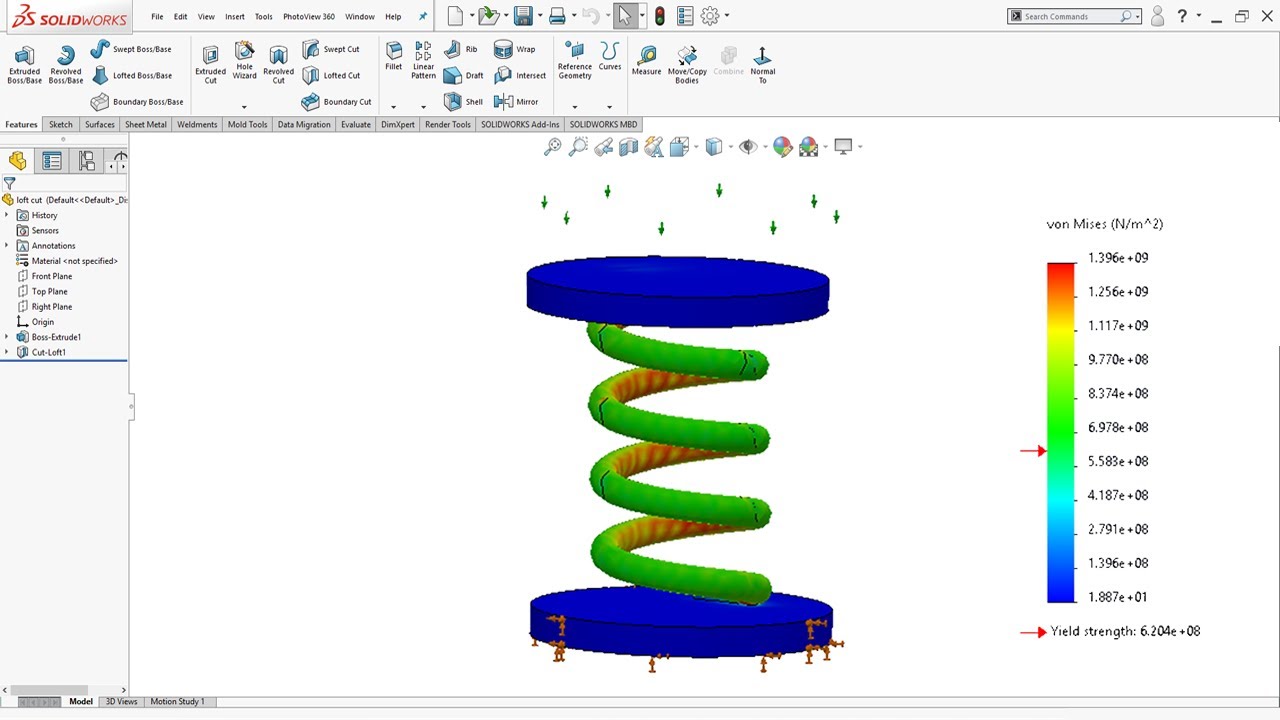

Advanced Structural Analysis

Define springs between any surfaces (flat or curved) with customizable stiffness (axial, torsional, bending, anisotropic).

Improved Pin Connector Performance

Faster and more accurate results using a distributed coupling algorithm for pin connections.

Faster Meshing for Large Assemblies

Reduced meshing time by reusing midside nodes for repeated parts, improving efficiency in large models.

Automatic Detection of Underconstrained Bodies

Instantly flags rigid body modes in linear static studies, helping users quickly identify missing constraints.

Bonding Interactions with Offset Control

More accurate bonding behavior between curved or offset surfaces using a node-to-surface bonding method.

Why Choose

SOLIDWORKS for Designing?

SOLIDWORKS SIMULATION FEATURES

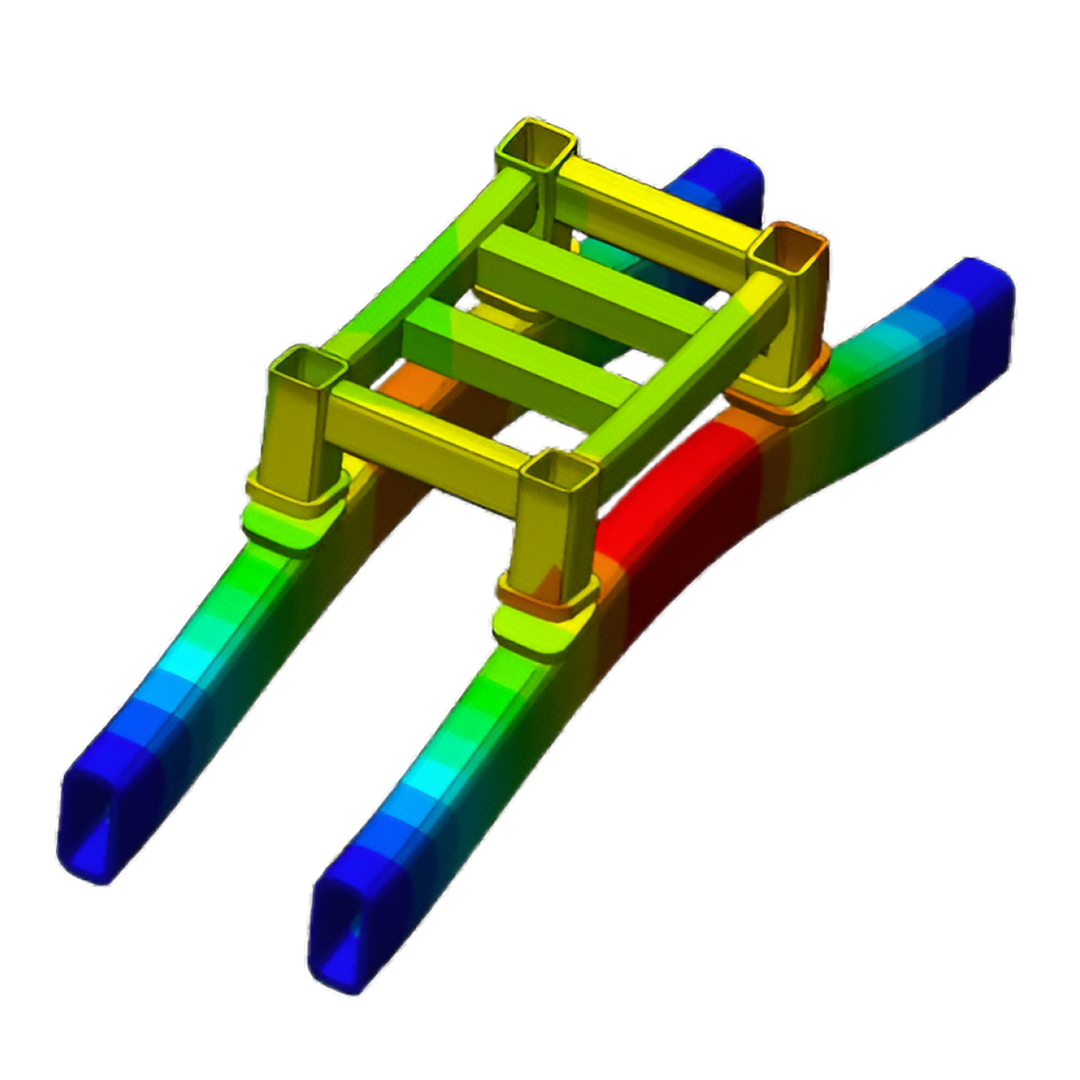

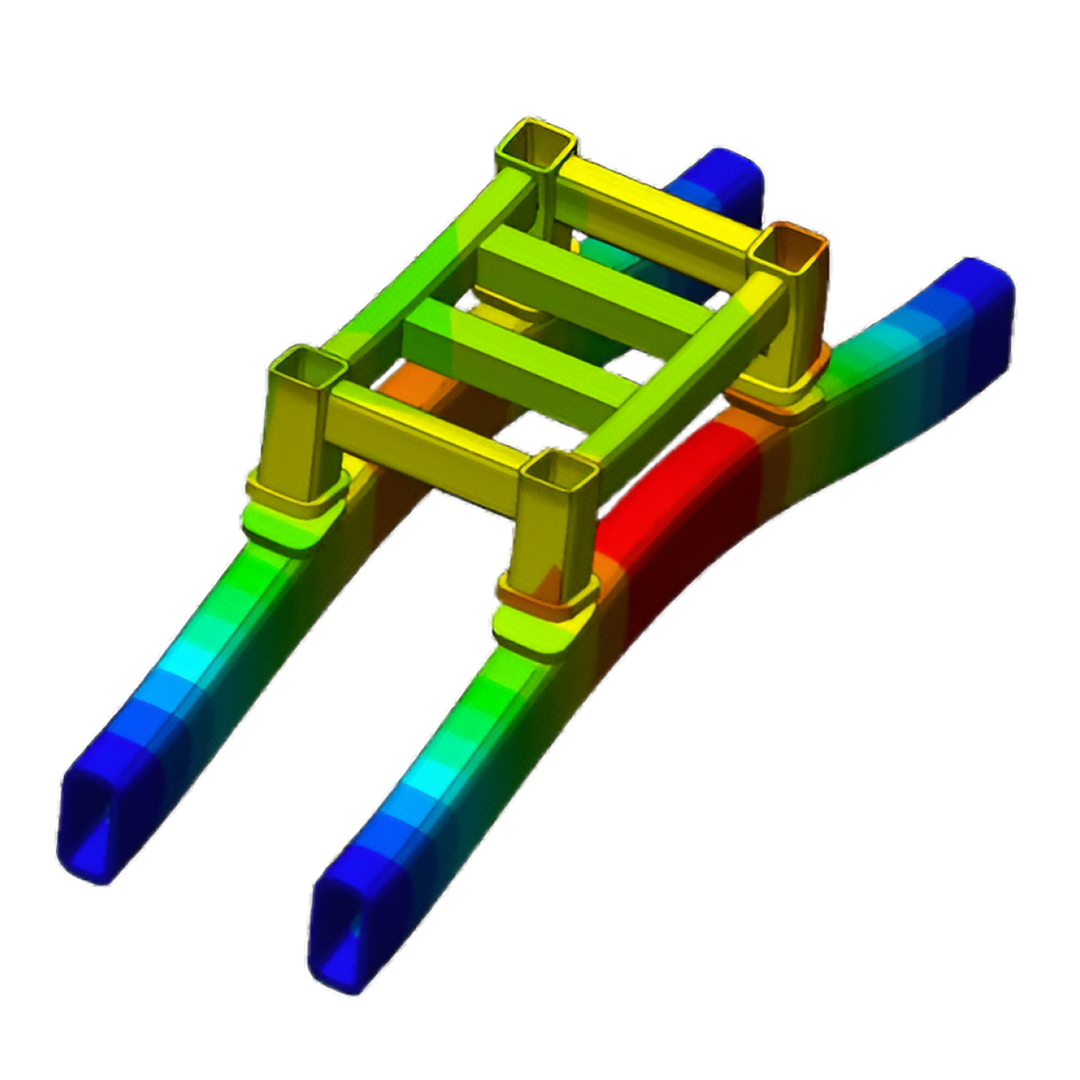

Advanced Structural Analysis

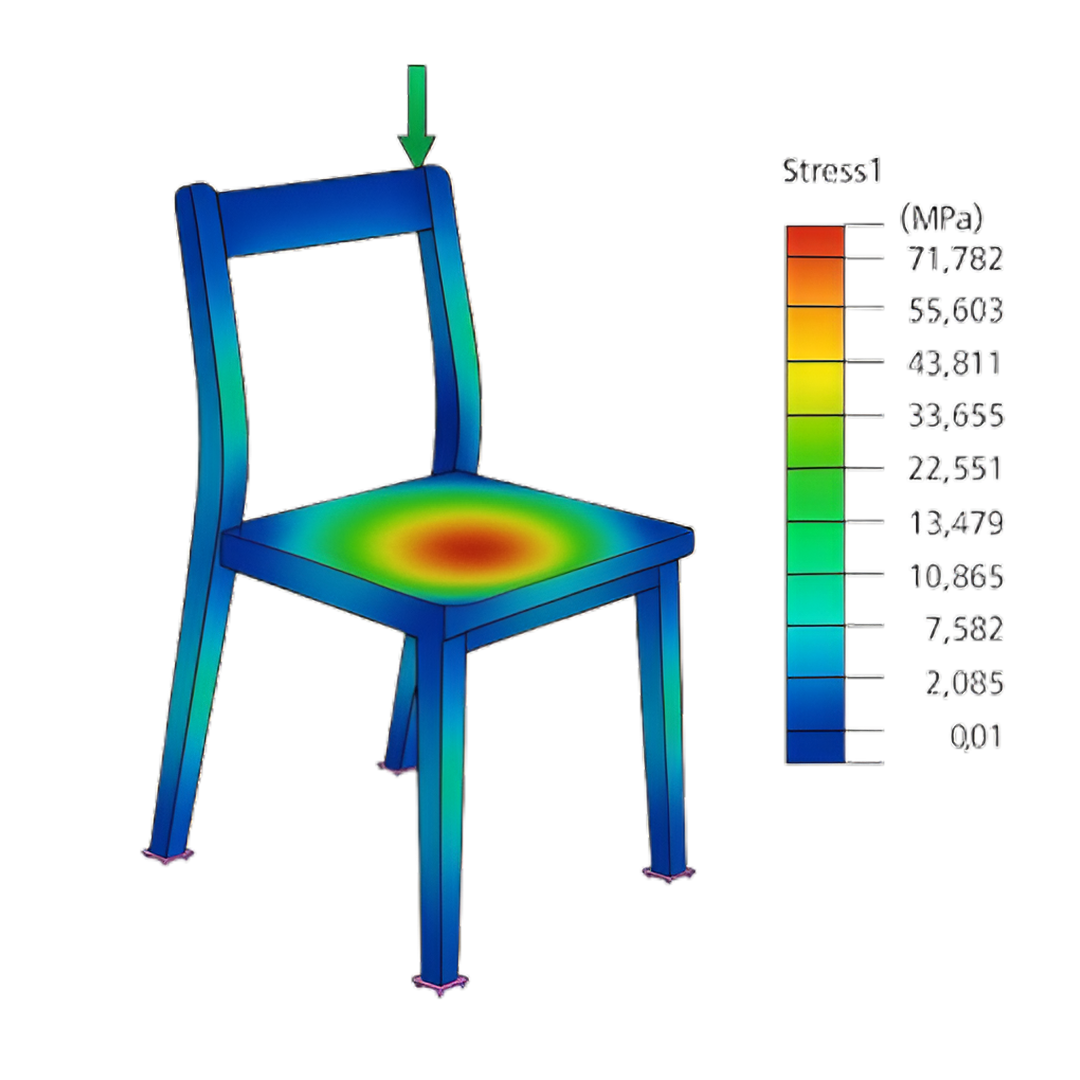

Test the durability and strength of your designs under various loads using powerful tools that simulate static and dynamic forces.

Real-World Load Testing

Simulate how your product will behave under actual usage conditions like pressure, vibration, gravity, and temperature.

General Spring Connectors

Create accurate mechanical interactions by connecting parts with virtual springs, replicating real-world flexibility and movement.

Faster Mesh Generation

Quickly prepare your models for analysis with high-quality mesh tools designed for accurate simulation results.

Accurate Simulation Results

Use SOLIDWORKS Simulation to get realistic results that guide your design modifications without trial-and-error physical testing.

Topology Optimization Tools

Refine your design by removing unnecessary material while maintaining strength, reducing weight and cost in the final product.

SOLIDWORKS Simulation Buying Options

Explore and Choose the Best Package that Meets Your Needs.

SOLIDWORKS Simulation Standard

Perfect for designers starting with simulation, this package covers linear static analysis for parts and assemblies, plus motion studies. It’s integrated within SOLIDWORKS, eliminating the need for external tools.

SOLIDWORKS Simulation Professional

Go deeper with thermal analysis, buckling studies, fatigue testing, and optimization. Best suited for teams that want to explore different conditions and improve product reliability before production.

SOLIDWORKS Simulation Premium

Handle the most demanding simulations with support for nonlinear materials, drop tests, and large deformation studies. Designed for advanced users, this package offers complete simulation capabilities for complex engineering projects.

Advantages of

SOLIDWORKS SIMULATION

- Easy-to-use tools with a powerful CAD interface

- Accurate simulations reduce reliance on physical prototypes

- Handle large assemblies with ease

- Lower overall development costs and shorten project timelines

| FEATURES | SIMULATION STANDARD | SIMULATION PROFESSIONAL | SIMULATION PREMIUM |

|---|---|---|---|

| Fully Embedded Analysis | ✓ | ✓ | ✓ |

| Communications | ✓ | ✓ | ✓ |

| Static Stress Analysis | ✓ | ✓ | ✓ |

| Fatigue Analysis | ✓ | ✓ | ✓ |

| Kinematic Motion (Time-Based) | ✓ | ✓ | ✓ |

| Kinematic Motion (Event-Based) | ✓ | ✓ | |

| Submodeling | ✓ | ✓ | |

| 3D Simplification | ✓ | ✓ | |

| Optimization | ✓ | ✓ | |

| Thermal Analysis | ✓ | ✓ | |

| Buckling Analysis | ✓ | ✓ | |

| Frequency Analysis | ✓ | ✓ | |

| Drop Test Analysis | ✓ | ✓ | |

| Pressure Vessel Analysis | ✓ | ||

| Nonlinear Analysis | ✓ | ||

| Plastic Deformation/Residual Stress | ✓ | ||

| Composite Material Analysis | ✓ | ||

| Dynamic Analysis | ✓ | ||

| Forced Vibration Analysis | ✓ |

Related Articles