In today’s fast-paced engineering landscape, precision and efficiency are not optional—they’re mandatory.

As industries demand faster development cycles and more reliable products, simulation-driven design validation has become a critical phase in product development. Choosing the right type of analysis—static or dynamic—can significantly influence the success of a project. With modern tools like SOLIDWORKS Simulation, engineers can better understand how products behave under various load conditions and ensure they meet performance requirements before entering production.

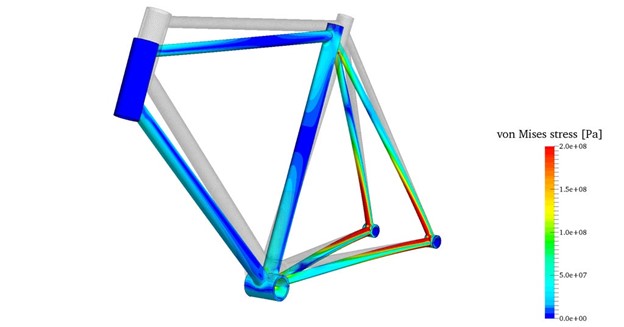

At its core, static analysis is used when loads are constant or applied gradually, without considering time-dependent effects. Think of it as a snapshot—an evaluation of how a product reacts to forces like weight, pressure, or tension when those forces don’t change rapidly. This approach is ideal for most mechanical design applications like mounting brackets, pressure vessels, or structural frames. For example, when designing a wall-mounted shelf, engineers can use SOLIDWORKS to conduct a static simulation to determine whether the shelf will deform or fail under a steady weight. The analysis includes measurements of stress, strain, and displacement, helping designers quickly assess the safety and reliability of the structure.

When Dynamic Simulation Becomes Essential

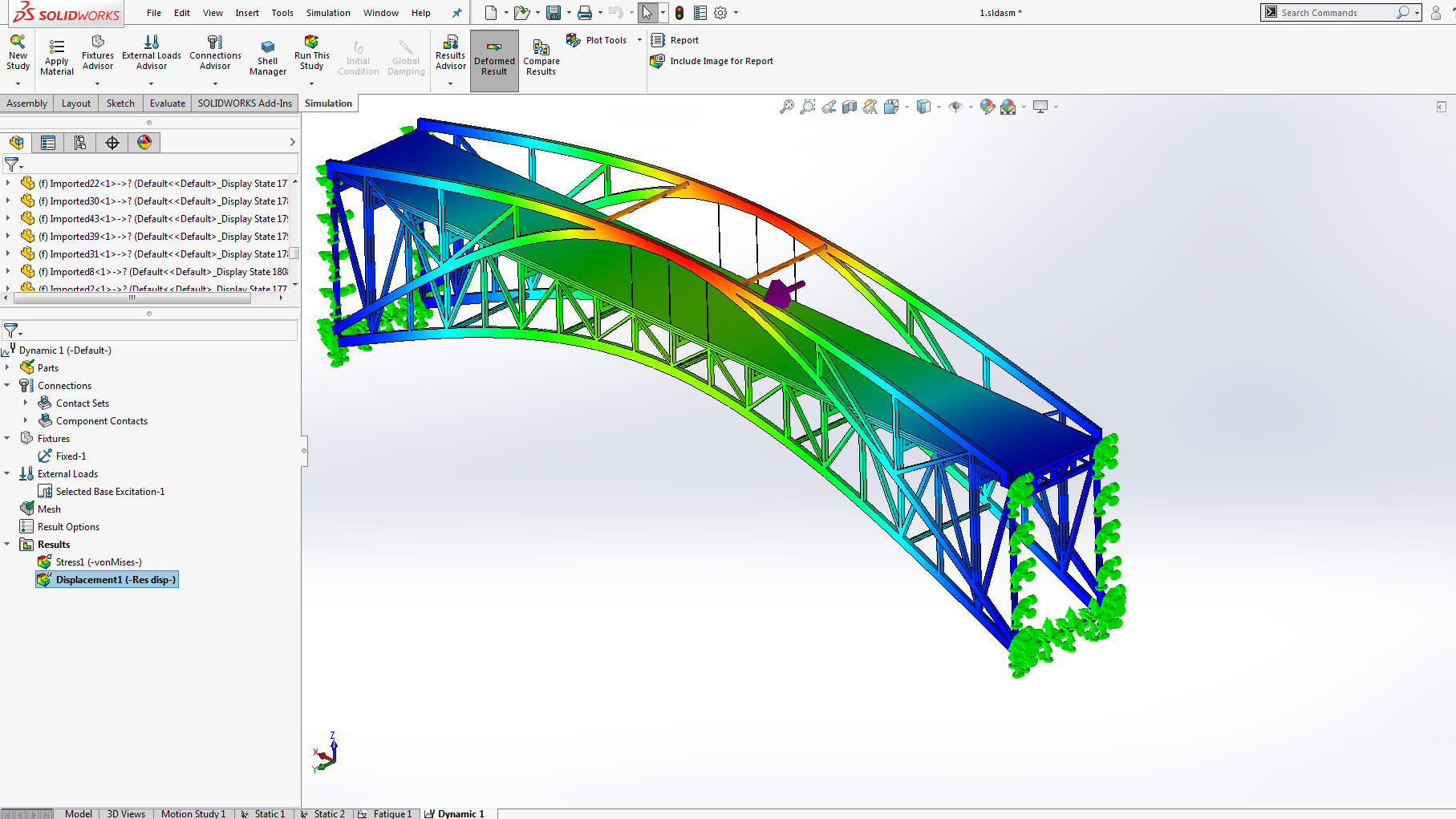

However, not all loading conditions are so predictable. In many real-world applications—especially in industries like automotive, aerospace, or manufacturing—forces can vary significantly over time. That’s where dynamic analysis becomes essential. Dynamic simulations account for motion, time-dependent forces, and inertia. Scenarios such as a car crashing into a barrier, machinery parts vibrating at high frequency, or buildings subjected to seismic activity require dynamic studies to capture the full range of structural behavior. SOLIDWORKS Simulation Premium offers advanced capabilities like modal, harmonic, and time-history analyses, allowing engineers to explore these complex phenomena in depth.

The key to choosing between static and dynamic analysis lies in understanding the nature of your loading conditions. If your application involves constant or gradually applied loads, static analysis provides a quicker and more resource-efficient way to validate your design. It’s less computationally intensive and easier to set up, making it ideal for early-stage design iterations. But when your project involves shocks, vibrations, or time-varying forces, dynamic simulation is the more accurate path. Ignoring dynamic effects in such cases could lead to incorrect assumptions, compromised product safety, or costly recalls.

Smarter Simulation with SOLIDWORKS and 3DEXPERIENCE Cloud

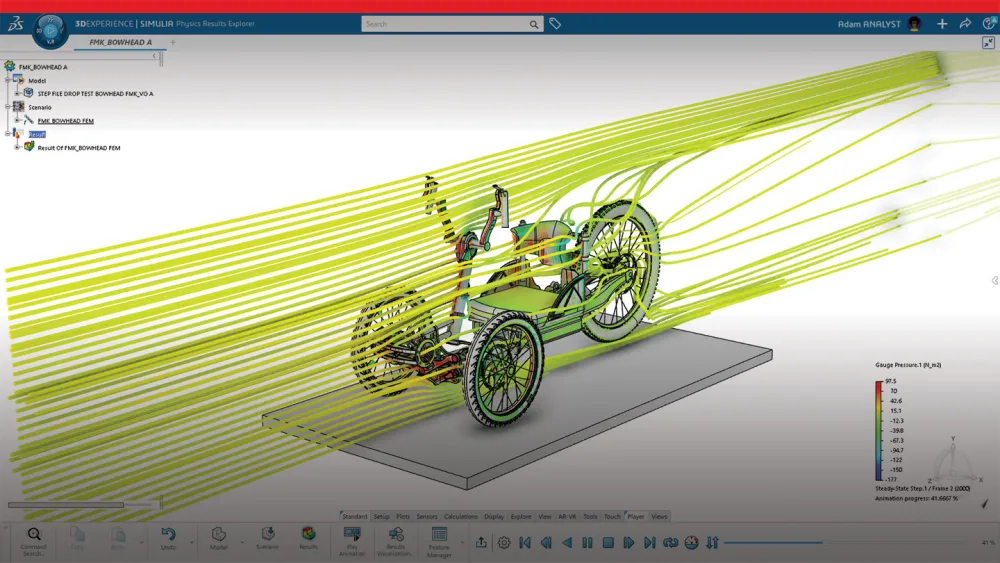

What makes this choice even more impactful today is how modern tools like SOLIDWORKS Simulation 2025 have evolved to make both methods more accessible. With improved solver speed and a more intuitive user interface, even engineers without deep simulation expertise can conduct meaningful analyses. Wizards and pre-loaded templates help users choose the correct study type based on input conditions, which improves both accuracy and efficiency. Moreover, the integration with the 3DEXPERIENCE platform enables users to perform simulations on the cloud, removing the limitations of local hardware and enabling teams to collaborate and share results in real time. This cloud-based approach not only increases accessibility but also ensures that data is stored securely and can be accessed from anywhere—an essential feature in today’s remote and hybrid work environments.

The manufacturing sector is increasingly leaning on simulation to minimize prototyping costs and reduce development time. Companies are looking for ways to cut down on physical testing while still ensuring the robustness of their designs. This is especially true in industries that deal with high-risk or high-precision applications. For instance, in medical device manufacturing, both static and dynamic simulations are crucial—static for load-bearing elements and dynamic for understanding how the device behaves during operation or under fluctuating physiological conditions. With SOLIDWORKS, engineers can simulate both conditions within a single, integrated platform, improving productivity while ensuring compliance with strict industry standards.

Additionally, having access to both static and dynamic simulations allows engineers to adopt a multi-tiered validation approach. Early static simulations can be used to refine the design structure quickly, while more comprehensive dynamic studies can later validate the final product under real-world conditions. This layered strategy not only improves development speed but also enhances the reliability of the final product.

In conclusion, understanding the difference between static and dynamic simulation is essential for engineers striving to build safer, smarter, and more reliable products. The enhanced capabilities in SOLIDWORKS Simulation 2025, especially when used in conjunction with 3DEXPERIENCE cloud tools, allow for greater flexibility, accuracy, and collaboration. Whether you’re designing a simple bracket or a high-speed industrial machine, choosing the right simulation method—and using the right tools—can make all the difference in your design journey.